Commercial kitchen layout matters because random planning slows down staff, contaminates food items, or even leads to serious injuries. Restaurant kitchens, the backstage where all the magic happens, are hectic places with equipment, storage area, staff, and ingredients. All these must be well organized to transfer the quality produced in the back of the house to the front. Here are some compelling reasons to take commercial kitchen equipment layout to heart.

1. Seamless Workflow & Efficiency

When you have a well-thought-out kitchen setup, commercial benefits will naturally flow. An ordered workflow will, first and foremost, improve efficiency. An effective commercial kitchen equipment layout can help structure daily tasks, giving the staff easy access to every piece of equipment and sufficient space to move around. Each kitchen process is fulfilled smoothly when every tool is in a fixed place. A kitchen layout for restaurants with equipment grouped by function or type can also prevent interruptions between different tasks. Plus, you will get the maximum even out of tight spaces.

2. Speed

Speed is one of the most sought-after features of frequented restaurants. No one in today’s fast-paced world can put up with waiting. You may have to beg for an extra second when back-to-back orders press you. A structured commercial kitchen equipment layout accelerates your operation. Machines, supplies, and ingredients placed within staff’s easy reach will reduce downtime. With everything at an arm’s distance, employees will know what is where, and all the procedures, from prepping to serving, will flow in an automated manner.

3. Higher Output

A smoother, faster, and more efficient workflow naturally transfers to your production rates. Chefs and food prep staff can complete their assigned tasks without cutting into one another’s. Even an unnecessary short trip to a sink or refrigerator can slow down cooking and service. A restaurant kitchen plan will improve communication between food preparation and cooking areas, avoiding such delays. Besides, if everything is preorganized in a commercial kitchen equipment layout, employees won’t have to worry about the fine details of safety and cleaning codes.

4. Reduced Costs

Serving speed and workflow efficiency can also reduce operational costs in several ways. First, with an increased pace and maximum space use, you can have more room for storage, allowing bulk purchases of ingredients. Second, an ergonomic working area boosts employee morale, lessening the toil and rush. Your team members can work more comfortably with almost no stress. This can not only make them more productive but also shrink labor turnover. Also, a well-structured commercial kitchen equipment layout means less need for costly modifications in kitchen setup.

5. Safety

Restaurant kitchens pose many risks with sharp tools, heavy-duty utensils, cleaning chemicals, boiling liquids, and more, not to mention the consequences of possible poor ventilation. An effective commercial kitchen equipment layout minimizes all these dangers and creates a more accident-free workspace. Risk prevention can save you roughly 42,000 dollars in compensation costs per employee. The same is true for food safety. The convenience and accessibility of storage areas, cleaning agents, and handwash sinks minimize food handling and cross-contamination risks.

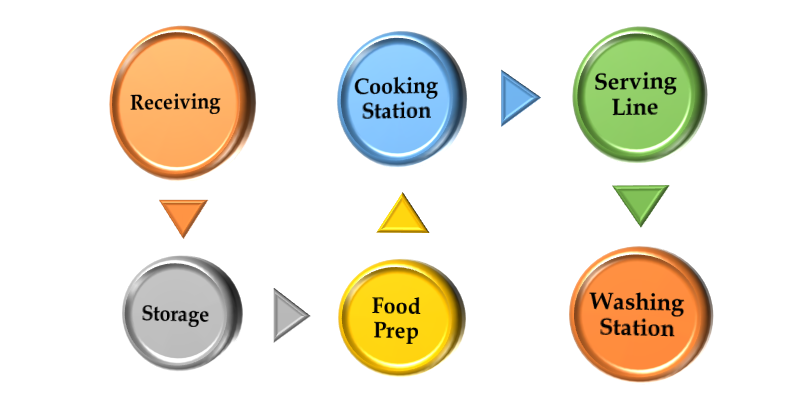

Components Of Commercial Kitchen Equipment Layout

Commercial kitchen equipment layout is primarily the arrangement of equipment, available floor space, and countertops to provide maximum workspace efficiency for kitchen staff. Therefore, when considering how to design a commercial kitchen layout, you should first decide where to place various machines, gadgets, and supplies. The goal is to create a spacious and comfortable area that can handle the hustle during business peaks. Think deeply about the best organization of the following components before choosing your restaurant equipment layout.

1. Receiving & Storage

The commercial kitchen equipment layout starts with the organization of the receiving area. An ample parking lot during offloading and shipping is crucial. The incoming inventory must be transferred to your walk-ins, reach-ins, or storage cabinets. When installing these, try to leave sufficient room to effortlessly maneuver trucks & dollies around the receiving and storage areas without spills. The proximity of the receiving dock to the walk-in coolers and freezers helps accelerate the process, lower labor, diminish the need for food transport carts, and keep your perishables safer.

2. Food Prep

The food prepping station is the core of a commercial kitchen equipment layout. The received and stored ingredients will move to the food preparation area when needed. The loading dock must not be very close to the food prepping station to not slow down the procedures here. However, more distance means more time. Refrigeration units can provide effective communication between the two. Also, plan your commercial sinks in this part of the kitchen and designate each for handwashing, warewashing, and ingredient rinsing separately.

You may need several food prep areas, depending on your business type. The preparation of proteins for cooking will be different from dough-based products or fresh produce. Most of your food prep equipment will be in this part of the kitchen. With commercial work tables, refrigerated prep tables, condiment stations, and chef bases, you can have a smartly designed food prepping space and ample storage for ingredients and smallwares. You can also utilize the vertical space with restaurant shelving units to stock food items and kitchen essentials.

3. Cooking Station

The cooking station is usually the heart of the commercial kitchen equipment layout. The place will house heavy-duty cooking equipment like ovens, fryers, ranges, and cookware like pans, pots, and woks. The cooking volumes and restaurant size will specify how many appliances you need. Using combi equipment for menu versatility and space efficiency might be wise. Choosing range-match equipment can create a seamless battery of multiple cooking units. You can also consider developing independent sections, like a frying station, baking section, or grilling area.

Two things merit extra diligence in sketching your commercial kitchen equipment layout for this station. First, proper ventilation is a prerequisite for remaining code-compliant, providing a comfortable working space for chefs, and improving the customers’ dining experience. You must install commercial kitchen hoods over cooking units to catch and expel grease-laden vapors, excess heat, and undesirable odors. Second, a smooth communication line between the cooking and serving stations is necessary to track orders and quickly deliver finished meals to guests’ tables while still hot and fresh. Many facilities now benefit from a digital kitchen display system for this purpose.

4. Serving Line

The operations to this point happen at the back of the house. However, the serving line is the face of your commercial kitchen equipment layout. Its organization directly reflects customer satisfaction. The serving station must be as close as possible to the dining area. Keeping insulated food carriers and commercial carts around is a good idea to streamline the servers’ jobs and hold the ready-to-serve recipes hot. You may often have to precook meals to catch up with orders during peak times. Food holding and warming equipment can help retain the taste, texture, and freshness of hot-served meals in such cases.

5. Washing Station

A hygienic commercial kitchen equipment layout is as vital as menu quality for operating a profitable restaurant and following health and safety regulations. All the tools used so far will end up in your washing station. Therefore, you must have enough commercial dishwashing equipment and dinnerware storage units. It is recommended to have only the warewashing sinks in this area for sanitation. Plus, carts and dollies can be helpful to carry the rinsed utensils back to the food-prepping, cooking, or serving stations.

5 Trendy Commercial Kitchen Equipment Layouts

Learning the basics of commercial kitchen equipment layout is the first step for a successful foodservice enterprise. 5 restaurant kitchen plans have proven helpful and gained popularity, and one of these common layouts may suit you or inspire you to set up your unique conception.

1. Island

The island commercial kitchen equipment layout pivots on a central cooking station. All the cooking equipment makes up the island, surrounded by other stations. Placing the washing station on the island perimeter close to the kitchen entrance and the serving line close to the exit will enable a smoother flow. This setup frees a vast open area for employees to work without blocking each other. The island layout also facilitates managers’ supervision. If you have a big kitchen, you can consider this option.

2. Galley

In a commercial kitchen equipment layout with a galley style, workstations are located in two parallel lines with a large hallway in between. The corridor in the middle enables a crowded team to work comfortably. Again, it is recommended to spare the kitchen entrance for the washing station and the exit for the serving line. The galley layout makes each appliance and station easily accessible and prevents jams due to foot traffic. It maximizes space use and productivity, which is ideal for small restaurants with limited room. If you operate a large kitchen, you can combine the galley with the island layout for a more efficient workflow.

3. Assembly Line

The assembly line puts food prepping, cooking, and serving stations side by side on a single row, with the storage and washing stations behind the row. Therefore, food items follow a stable order, promoting repetitive actions. Thus, you can feed crowds quickly without cross-contamination concerns. Speed, the primary benefit of this commercial kitchen equipment layout, makes it almost the most common. It is perfect for high-volume demands in quick-serve restaurants, fast-food outlets, or facilities that often serve the same menu.

4. Zone Configuration

The zone commercial kitchen equipment layout divides the kitchen into several blocks for each station, with heavy-duty equipment installed against the walls. The kitchen looks sectioned into multiple smaller rooms. The design creates plenty of open space for smoother flow and easier communication across various stations. As the center is wide open, it also allows easy supervision. This station-based configuration works best in professional high-end restaurants that offer diverse menus and employ a lot of staff, each specialized at certain tasks.

5. Open Layout

The open layout is sharply different from other commercial kitchen equipment layouts. It prioritizes visuality and removes the walls between the dining area and kitchen. Customers can watch the whole meal cooking process in action. Suppose you have skillful chefs who can transform cooking into a culinary performance. In that case, you can create a uniquely entertaining dining experience for your guests. The concept is increasingly gaining popularity in upscale restaurants. Smaller establishments can also maximize their production and space use with shorter trips from the kitchen to the delivery area.

Final Thoughts On Commercial Kitchen Equipment Layout

Whether you pick an existing trendy commercial kitchen equipment layout or configure your typical setup, your prime concern must be ergonomics rather than appearance. Besides, it would be best if you did not neglect sanitation, food safety, and fire prevention regulations. Your kitchen does not have to shine but address your specific needs. A carefully arranged format can help retain employees, diminish time and product waste, and thus boost profits. Always visualize your kitchen and the following key points while shaping your opinions on how to design a commercial kitchen layout.

- Stations, appliances, utensils, and other kitchen tools should be designed to streamline your operations, increase the speed and throughput, and offer the most comfortable working space.

- Your sketch pattern should also promote proper ventilation, sanitation, maintenance, and supervision.

- A flexible and modular composition strengthens your hand when ready for renovation or expansion.

- Finally, you can always get professional guidance on design and layout issues for more innovative and smarter solutions.

You can also read our blog post to learn more about how Chef’s Deal helps you in your commercial kitchen design and layout.