Food packaging systems refer to all the materials, methods, and technologies used for wrapping food items. Modern life is replete with processed foods or precooked meals sold in packages for convenience. Although the purpose of packaging varies by product type, it serves one primary function: preserving food safety and quality. Additional benefits are extending shelf life, increasing sales, determining portion sizes, minimizing food waste, and displaying product information. This article covers common materials, basic concepts and methods, and labeling issues in food packaging systems.

4 Common Materials Used In Food Packaging Systems

Food packaging systems contain foodstuff to protect it from external damage during the supply chain, storage, marketing, and serving. Food packaging materials initially aim to provide this protection. However, the materials themselves must not be a vessel of contamination. The material used directly influences the safety, quality, and freshness during distribution and storage. Increasing social and environmental awareness brought about strict regulations. FDA 21CFR174 mandates that substances in direct contact with food must not release chemicals. Below are the four common materials used in food packaging systems.

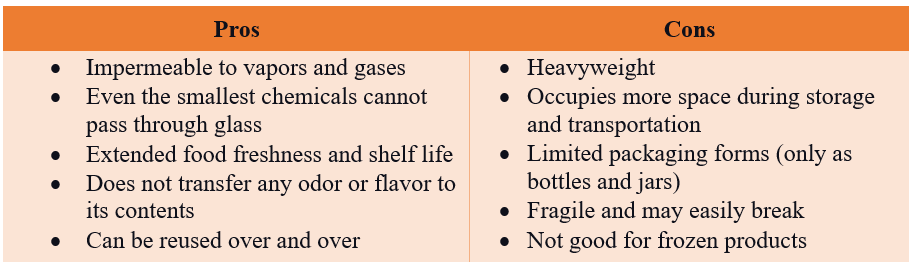

1. Glass

Glass has centuries of history in food packaging systems. Glass containers are popular as they are transparent, allowing customers to see the sealed items. They also promise years of protection when sealed tightly. Yet, the metal, cork, or plastic closures and lids can be a source of contamination. Still, glass is widely recognized as a safe container for beverages, baby food, and processed products.

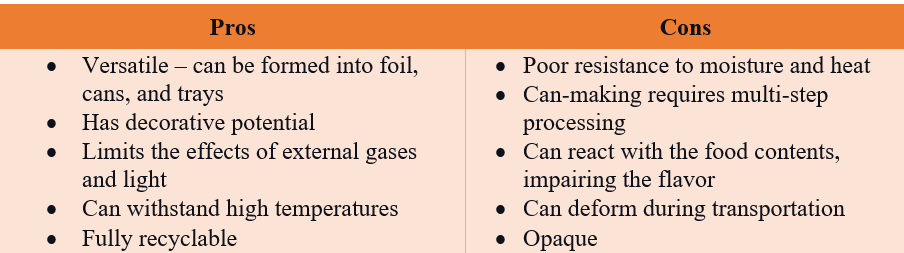

2. Metal

Metal is used in food packaging systems as aluminum and tin-coated steel containers. Storage and conservation of food and beverages in metal cans have been a staple in the industry for a long time. While aluminum cans are generally used for drinks, tin is preferred to can seafood, chicken, beef, pork, and vegetables.

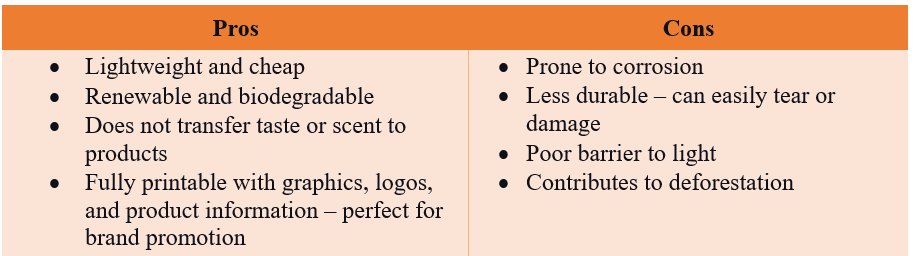

3. Paper

Paper and paperboard are substances formed into various popular food packaging systems. Paper bags and pouches are good for packaging dry groceries like flour and grains. Bakeries and patisseries can also use paper to wrap their bread and pastries. The thicker and harder boxes and corrugated boards can contain and carry frozen foods and bottled or canned liquids.

4. Plastic

Plastic is a polymer-based food packaging material that can be shaped into different designs. It dominates the food packaging systems in the form of bottles, pouches, trays, cups, foils, films, and others. It facilitates storing, displaying, and transporting frozen foods, cooked meals, snacks, fresh produce, dry ingredients, pastries, and more. Also, its production process is less costly than other materials.

Basic Concepts In Food Packaging Systems

The core of food packaging systems is the choice of packaging material. It requires balancing competing factors like durability, affordability, availability, ease of use, greenness, and consumer perspectives. The food type, intended use, and desired shelf life also play a role. These aspects are crucial in how food plants and foodservice operators choose their packaging systems.

1. Primary Vs. Secondary Food Packaging Systems

Food packaging systems cater to either primary or secondary packaging needs. Primary food packaging systems define the packaging consumers see and touch. Secondary packaging refers to larger packages that hold together multiple primary packages.

- Materials used in primary food packaging systems have direct contact with the package contents. Therefore, the selected material must be sturdy, provide strong chemical protection, and limit flavor and odor transfer. Canned drinks in reach-in refrigerators, candy bar wrappers in confectioneries, and bagged pastries in bakery display cases are examples of primary packaging. They should appeal to the end users with an elegant look, undeformed shape, and relevant product information.

- Secondary food packaging systems help operators during their inventory and storage applications. The primary purpose of secondary packages is to enable food transportation in large bulks and safeguard the products during transportation. Thus, the emphasis in material selection is on durability rather than appearance. Footprint also matters for more cost-effective food transport. Corrugated cardboards, large plastic boxes, and pallets are well-known examples.

2. Conventional Food Packaging Systems

Food packaging systems constantly evolve depending on emergent consumer demands, novel technologies, waste reduction issues, health concerns, and operational costs. The following methods have survived for decades in the industry, providing a good balance among these priorities.

- Bags: Displaying or carrying food in bags is a traditional food packaging system. Paper bags are gaining popularity as consumers consider them healthier than many other materials.

- Pouches: Flexible pouches are plastic containers that greatly benefit operators and consumers. These light systems only take up a little space during storage and display. Customers love them because they can feel the texture of the food.

- Cans: Marketing beverages and food in thin metal cans is a conventional practice. They can protect their contents for extended periods.

- Glass Bottles & Jars: From consumers’ perspectives, keeping foods and drinks in glass containers is the most dependable food packaging system. For foodservice operators, transparency means increasing impulse sales. Glass also promises extensive shelf life. However, shattered bottles and jars in supermarkets or food transport vehicles are almost indispensable.

- Boxes: Boxes are widespread food packaging systems made of paper, board, and metal. They often contain cereals, fast foods, frozen items, pizzas, and many more. Corrugated boxes of various sizes are becoming popular for food transportation and storage.

- Cartons: The material used in cartons is cardboard, often coated with plastic or tin. Everybody is familiar with egg and milk cartons.

- Clamshell Packaging: Plastic or paperboard clamshells feature two shells. Often, their contents are salads, sandwiches, produce, and cooked items. They offer great convenience for customers. For instance, when you buy BBQ ribs in a clamshell package, you can store, heat, and eat them in the clamshell.

- Wrappers: Aluminum foil and plastic film are almost the standard wrappers in the industry. Since they are practical, many facilities use them in their daily operations. You can quickly wrap a frozen fish or salad and firmly seal it with stretch film using different food packaging machines like vacuum sealers and film & shrink-wrapping machines.

- Trays: Trays are flat, usually thick paperboard, packages for storing meats, fish, and canned beverages. They have raised ends to prevent products from falling.

- Pallets: Wooden or plastic pallets enable distributors and wholesalers to carry large quantities of packaged products.

3. Rigid Vs. Flexible Food Packaging Systems

Flexible packings like films, foils, and clamshells are made of plastic, paper, or a combination. Rigid packaging includes glass containers, corrugated boxes, and cans made with hard plastics, cardboard, glass, or metal to carry fragile products. Each has certain benefits and drawbacks. Flexible packages are space-saving, greener, and lighter. They allow branding but provide less protection and can influence the flavor of their content. Solid packages are more durable yet pricier to manufacture and carry.

Methods Applied In Food Packaging Systems

Packaging food does not guarantee preservation. The meat will develop bacteria, or milk will go sour if not stored under optimally refrigerated conditions. Refrigerating, drying, picking, or using artificial preservatives are traditional ways to slow food spoilage. However, commercial establishments need improved methods to keep their products edible and fresh longer.

1. Vacuum Food Packaging Systems

What promotes bacteria growth or oxidation in food is the presence of oxygen. Vacuum packaging aims to remove all the air inside the package and around the food. Then, a vacuum sealer machine heats the edges of the package. The result is a fully airtight pack with no room for food spoilage. Many commercial kitchens and catering businesses adopt this process to store vast amounts of products. Thus, foods can retain their original flavor, aroma, and color, always looking attractive to customers.

2. Aseptic Food Packaging Systems

Aseptic food packaging systems use extreme heat to sterilize foods and packaging materials separately. Paper, plastic, and aluminum are layered together to form cups, trays, or pouches. They are then sealed hermetically. Milk, dairy products, coffee, soups, sauces, baby food, or fresh fruit juices can maintain their original taste and texture without refrigeration and preservatives. Thus, in ambient temperatures, you can display such merchandise on shelves for 6 to 12 months.

3. Modified Atmosphere Food Packaging Systems

Another method to improve the shelf stability of fresh products is the modified atmosphere pressure (MAP). This food packaging system is based on manipulating the gaseous atmosphere inside a pack. MAP is replacing the gases with a mixture of desired gases instead of removing all the gases. The purpose is to create a protective environment in the package to preserve and keep the contents fresh. Thus, MAP protects perishables like meat, poultry, seafood, cheese, and fresh produce from external and internal factors.

New Technologies and Trends In Food Packaging Systems

Changes in lifestyles and technologies emerge new consumer and retailer demands in food packaging systems. Convenience, speed, cost, and efficiency are becoming more important for operators. Also, customers are growing more health-conscious in everything they eat and drink. With the added “go green” movement, stricter codes now regulate the food packaging industry. The market had to adapt to evolving concerns and pressures by modernizing the food packaging lines and developing smarter and greener solutions.

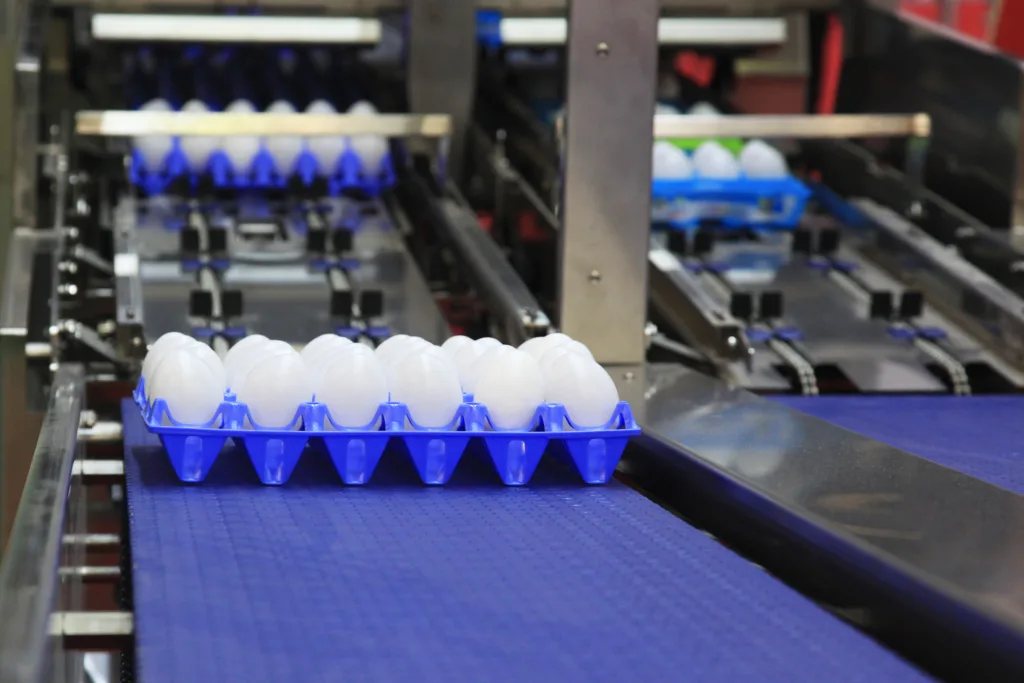

1. Automated Food Packaging Systems

Automation involves using robotics in industrial food packaging machines throughout the entire packaging process. Packaging robots perform all the primary and secondary packaging steps to build a seamless food packaging line. They open, fill, seal, label, palletize, and transport the packages. Food manufacturers are increasingly noticing the speed and convenience of automated systems to meet the growing demand for packaged foods. Increased production volumes, higher food safety, lower labor costs, precision, and consistency are some benefits of automated food packaging systems.

2. Smart Food Packaging Systems

Customer concerns, expanding e-commerce industry, and regulations have prioritized traceability in food packaging systems. People want to know all the processes and steps in the food supply chain to track the safety and authenticity of what they eat. Smart food packaging systems use sensor technology to detect, record, and report changes in food quality. Such intelligent food packaging systems benefit food manufacturers, retailers, and consumers. They have constant access to data about package tightness, storage times, temperature, freshness, and expiry dates.

3. Active Food Packaging Systems

Active food packaging systems also depend on smart technologies. The package includes an active compound that interacts with its contents to keep them fresh for longer. The interaction happens by absorbing unwanted elements or emitting antimicrobial substances. This procedure constantly regulates the moisture and oxygen levels around the packed food. Modifying the atmosphere inside the package extends the product’s shelf stability and enhances its sensory qualities. The active agent is often placed in pads, labels, or coatings.

Antimicrobial food packaging systems are among the most promising active packaging forms. They use antimicrobial substances in the packaging material or agents inside the package. The purpose is to kill pathogenic microorganisms and prevent food spoilage. These food packaging systems with natural antimicrobial agents are particularly good for delicate products like dairy, meat, poultry, bakery, and fresh produce.

4. Takeaway Food Packaging Systems

On-the-go food was already an integral part of modern life. People loved the convenience of drive-thru food pick-up. However, the recent surge in online orders has encouraged restaurateurs to find safer, more durable, and decorative takeaway food packaging systems. Consumers want their meals to remain clean, fresh, and hot from the kitchen to their doors. People who order delivery prioritize packaging, with 84% saying it influences their decisions. Stylishly packaging delivery foods can also boost sales through branding.

Clamshells, pouches, and plastic boxes are some widespread takeaway food packaging systems. They are also inexpensive. However, eco-awareness is increasing in society, so sustainability is gaining importance. Many consumers prefer paper and cardboard containers as they are biodegradable. That’s why restaurants often use cardboard boxes in their pizza delivery. Paper can benefit operators, too. They can customize printing on the box to reinforce their brand identity.

Labeling In Food Packaging Systems

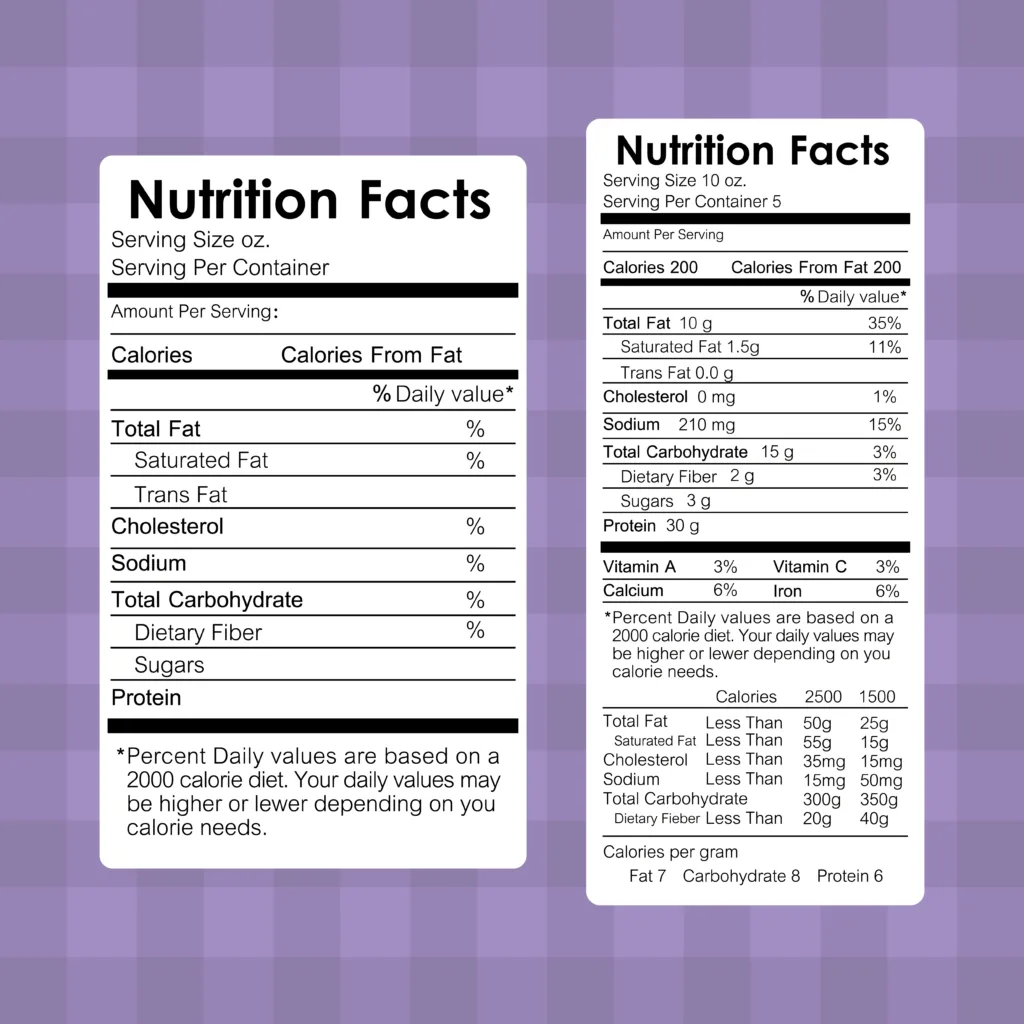

Labeling is a multi-faceted issue in food packaging systems. Companies may focus more on making the package as attractive as possible to affect consumers’ buying decisions. However, food labels are legal requirements regulated with strict guidelines by FDA. Food package labels must provide certain pieces of information to protect consumer health. FDA Part 101 details food labeling and directs the inclusion of the following data.

- Common name

- Net quantity

- Information about the manufacturer, packer, and/or distributor

- Ingredients

- Nutrition facts

- Allergens

Additionally, some states may require different dates on some items. Adding expiration, sell-by, or best-before dates on the package label can be necessary depending on the state and food.

Final Thoughts On Food Packaging Systems

Packaging is what grabs consumers’ immediate attention when buying food items. Customers will not pick a deformed package on a store shelf no matter what its contents are. The look and feel of a packaged product can be a powerful marketing means. However, food packaging systems mean much more than aesthetics for food production plants. Food safety must be the prime issue during the entire packaging process. The materials and methods used can have irreplaceable consequences on human health.

Technological developments and environmental concerns have diversified food packaging systems. Green technologies, cost reduction attempts, and user-friendliness have opened the way for automated and intelligent food packaging systems. Plus, sustainability has promoted biodegradable materials and active food packaging. Players in the industry should incorporate individual, social, environmental, and economic factors to address such concerns.