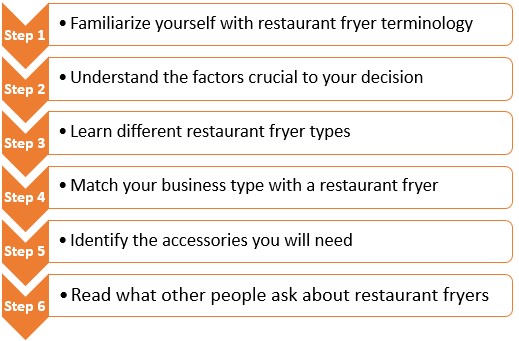

Chicken fingers and nuggets, buffalo wings, onion rings, french fries, mozzarella sticks, tacos, donuts, corn dogs, and potato croquettes are among the most iconic recipes in American foodservice facilities. Few hungry stomachs can reject such mouthwatering flavors: crispy outside and soft inside. A restaurant fryer is the creator of this culinary magic, making you lick your lips all day. The need for one is simple, but choosing the best isn’t, with so many types and features. This blog will lead you to the commercial deep fryer matching your expectations step by step.

Restaurant Fryer Glossary

You might encounter terminology in manufacturer spec sheets or manuals when browsing restaurant fryers. Below is a sample of the most central ones that will contribute to your understanding of deep fryers.

- Frying Area: It is the maximum space in your restaurant fryer pot for cooking. It is specified as length by width. A fry pot with a 50-pound fat capacity will roughly have 18×18 inches of frying area.

- Cold Zone: Also known as the sediment zone, the cold zone describes the area below the heating elements. The temperature in this part of the oil tank is cooler. If breading particles or other food crumbs continue cooking, they degrade oil and cause a burnt after-taste. These particles will stop cooking in the cold zone, reducing oil breakdown and improving taste quality.

- Recovery Time: Refers to the time it takes for the oil to reach frying temperatures when a new fry cycle starts. If this interval is longer, products will absorb more fat and get greasier, and the service will be sluggish.

- Basket Hanger: Some restaurant fryers have removable hangers to hold the fryer basket after frying is done. They help filter excess oil from the finished products.

- Drain Valve: A small opening, usually 1 or 1.1/4 inches, for draining oil from the fryer tank.

- BTU (British Thermal Unit): Refers to the energy generated by gas cooking equipment per hour. Higher BTU ratings mean more gas consumption but faster heat-up and recovery times, crucial during extreme peak periods.

Key Factors For Buying A Restaurant Fryer

As you move towards the best restaurant fryer matching your expectations, attention to the factors below may make slight or sometimes significant differences in performance. While reading through these points, it’d be wise to consider your overall kitchen layout, existing cooking equipment, ventilation system, menu items, and production volumes.

1. Fuel Type

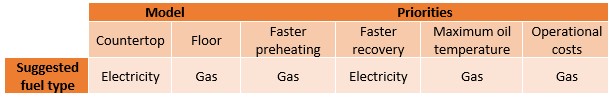

Restaurant fryers are powered by electricity or gas. Which one is more efficient and affordable is a never-ending question. One marked visible distinction is the position of heating elements or burners. Commercial fryer electric models have burners sitting at the bottom of the oil tank, contacting directly with the oil. This assures faster recovery times between fry cycles. The heating elements of commercial gas deep fryers can be inside or outside the tank. They’re renowned for preheating more quickly. Plus, maximum oil temperature is higher in gas fryers, and you can alternate between natural and propane gas.

Comparisons are based on recovery time, installation, and operational expenses. Your operational needs will tell you the best option. For example, if you run a high-volume kitchen with uninterrupted orders, faster recovery between batches should be your top priority. However, heat-up speed counts more than recovery time for a school cafeteria or a similar facility delivering dishes only at intervals. Also, considering the affordability of each energy source, gas is more suitable with higher-capacity restaurant fryers and electricity with compact countertop models.

The table below can give you a rough idea of what works best for you, depending on your priorities and choice of restaurant fryer.

2. Configuration

Restaurant fryers can be configured in three ways. Commercial countertop deep fryers are perfect for establishments tight on floor space. Floor fryers for restaurants stand on stainless steel legs with adjustable feet, and lastly, some models can have casters for mobility. Because they can produce larger batches, their recovery time is faster. That also means they consume more energy. They can produce consistently savory products for hungry crowds and are preferable for high-volume operations. Some floor fryers are called restaurant range or multiple battery units. These can be banked with up to six other fryers for a greater yield and continuous lineup.

Another configuration point is the number of pots. All restaurant fryers – countertop or floor – have a full-pot or split-pot design. A large single oil tank in full-pot units can accommodate one full-size or two half-size fry baskets. Split-pot models have two separate vats that can hold one or two baskets. The twin-tank commercial deep fryers enable you to fry two different menus without flavor transfer.

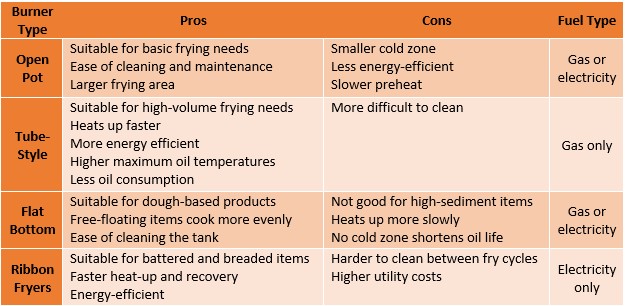

3. Burner Style

Burner style, also known as fry pot type, refers to the shape and position of heating elements in a restaurant fryer. This influences energy efficiency, taste, sediment zone, preheating speed, and recovery times. Therefore, each one can work better with particular menu items.

- Open-Pot Fryers: Burners are placed on the exterior of the oil tank, so they first heat the metal pot, which then transfers the heat to the oil. The tank narrows into a “V” shape at the bottom, creating a minimal cold zone. Therefore, they work best with low-sediment lightly-breaded items like fries, onion rings, or chicken tenders. Since they have a larger frying area, you can also cook high-sediment fried chickens. Yet, you should be more careful about cleaning bread and batter crumbs not to cause burnt after-taste.

- Tube-Style Fryers: These restaurant fryers have tubular burners fixed above the pot bottom. This frees a sizeable cold zone below the burners for sediments to collect, minimizing oil-degrading and increasing oil lifespan. Gas flowing through the tubes submerged in the fat tank speeds up the preheating. Tube-type fryers are ideal for high-sediment, heavily battered dishes like chicken, fish, or other freshly breaded foods.

- Flat-Bottom Fryers: They’re similar to open-pot restaurant fryers in design, but their fry pot looks like a large square. Since they are shallow, they don’t have a cold zone. Therefore, they are suitable for only some specialty dishes like donuts, funnel cakes, or tortilla chips. These low-density items float freely in the hot oil. The wide oil tank enables you to handle orders without delay if you serve only dough-based items.

- Ribbon Fryers: Powered by electricity, ribbon-shaped heating elements run through the oil tank to heat the oil directly. They combine the benefits of tube-style and flat-bottom fryers, so they’re more versatile. They can be used to fry many different products in various volumes. They require more frequent cleaning between batches, especially when cooking heavy-sediment foods. You can lift the ribbon element when cleaning your restaurant fryer.

4. Size and Capacity

Size relates to how much counter or floor space you can spare for a restaurant fryer in your kitchen. You also need to consider your menu type. You can manage french fries orders with a countertop deep fryer or commercial air fryer because fries are small items that can fit any-size fryer. It would be practical to match the size and density of your menu items with the fryer tank’s dimensions. The oil tank should be large enough to accommodate whole chicken parts or more oversized items.

Finding the right size is also about the restaurant fryer’s maximum fat capacity. Your choice will depend on your volume requirements. Because french fries are the most frequently fried items, manufacturers generally size their commercial deep fryers by pounds of fries per hour. You can always trust 1.5-2 times the oil capacity to measure an accurate production capacity. For instance, a deep fryer with a 60-pound fat capacity will produce 90-120 pounds of fries an hour.

5. Cleaning And Filtration

Oil filtration and regular cleaning of restaurant fryers directly affect the performance, taste quality, and oil consumption. Oil constitutes the most significant part of operating a deep fryer. Therefore, it’s not economical to change it after each batch. Proper filtering allows you to use the same oil several times without sacrificing flavor. How many times you can filter and reuse the oil relies on your frying volumes.

Some restaurant deep fryers have a built-in oil filtration system doing the whole job in one step. The system automatically drains the used oil, filters it, and refills the tank. They are a bit pricier but a reasonable investment. They’ll extend the oil’s life and rid you of the mess and hassle of handling used oil. If you have enough space for a floor model, buying one with an onboard oil filtration system will save you money in the long run. Plus, modular multiple-battery units can be connected to one filter system.

6. Controls And Advanced Features

Restaurant fryers with manual controls are straightforward and cheaper but require more operator attention. Each oil has a smoke point, a specific temperature when the oil will start creating foul odors and a burnt taste. This point varies between 400 and 450 degrees, depending on the oil type. It’s hard to track oil temperatures during a busy shift. So, it would help to control oil temperature for high-trafficked businesses automatically. Computerized programmable controls let operators adjust oil temperatures and cook times independently for different food items. They’re more costly but can improve quality and safety.

Another cutting-edge technology in today’s restaurant fryers is the auto-lift feature on programmable units. Preparing multiple menus simultaneously in several fry baskets requires a lot of care. The auto-lift system lowers and raises the basket at preset times. This feature can help you diversify your menu items and deal with recurring orders at peak times without worrying about food burn.

Restaurant Fryer Types

It’s common to associate restaurant fryers with only electric and gas deep fryers. They have an oil tank filled with hot oil. You dip food items in a batter or breading mixture, submerge them in the oil with a fryer basket, and lift the basket when the products get golden brown. Delivering large batches of dishes in this way is almost the norm. Here are other commercial deep fryers, each designed for unique operation requirements.

1. Commercial Pressure Fryers

Commercial pressure fryers also rely on cooking in hot oil as in deep-fat fryers. Although they are a bit pricier upfront due to the added pressure-cooking technology, they offer some benefits, reducing operational costs. First, they feature a larger frying vessel with a clamshell lid. This design locks in the air, and pressure speeds up the cooking process. The high pressure minimizes the need to filter and drain the used oil. Large, boned proteins will gain a perfectly crispy crust and juicy flesh with less fat and up to 15% shorter cook times than deep-fat fryers.

Although commercial pressure fryers were initially electric, gas models are also available. The high-speed cooking with pressure makes them energy-efficient regardless of the fuel type. Faster cooking times and fewer oil filtration cycles make them ideal for businesses with unexpected peaks. Many of these restaurant fryers promise up to 30 cook cycles without needing to filter the oil. Preparing fried chicken menus in large batches with pressure fryers has become the norm for many restaurateurs.

2. Commercial Air Fryers

Frying imparts unique flavors to dishes. For some people with healthier eating concerns, it also means extra calories and possible health hazards. Commercial air fryers address the growing need for a grease-free diet. The convection and radiant heat technology in these countertop electric restaurant fryers blow hot air inside the frying area to fry products with almost no oil. Therefore, customers can still dig in their favorite chicken wings or battered seafood without worrying about calories.

Greaseless cooking in air fryers removes many of the hassles in deep-fat fryers. Frequently filtering and dumping used oil causes extra mess and labor. The powerful fans inside air fryers do the frying with minimum fat. This also removes the restaurant hood requirement. However, air fryers are compact units. They can’t pace up with the high-volume demands of busy facilities. Plus, they aren’t suitable for frying multiple items simultaneously. If you have countertop space, you can have one as an extra but not as the only fryer in your facility.

3. Ventless Fryers

Ventless fryers aren’t very different from typical deep-fat fryers, but they don’t require an exhaust hood. All grease-generating cooking equipment needs to be used under a hood connected to some ductwork. These restaurant fryers feature an onboard filtration system that completes the filter cycle in a few minutes. Oil draining, tank cleaning, and filtering happen with the turn of a valve. This innovative design of the ventless fryers can extend oil life by at least 50%.

Why should you need a ventless fryer? Mounting hoods for each appliance may not be allowed or feasible due to some legal restrictions, building structures, or cost. They may not be practical or permissible in historical buildings, offices, mall kiosks, low-ceiling kitchens, or on top floors of high-rise buildings. In such cases, you might have to redesign your kitchen. Therefore, although ventless restaurant fryers can be more expensive than traditional fryers, the final cost will be much less.

4. Specialty fryers

Restaurant fryers can cook a vast array of products. Yet, certain items may require a different design and construction to yield better results. The most common specialty fryers are corn dog fryers and donut fryers. They are powered by gas or electricity and are available in countertop and floor models. Fuel type doesn’t make a big difference in these commercial deep fryers because they’re for delicate foods that fry quickly, whether the unit is powered by gas or electricity.

Outdoor fryers feature a portable design with heavy-duty casters and a push handle for easy maneuvering. They are fueled by gas for convenience. Easy connection to a propane tank through flexible hoses means you can fry and serve products hot on site. The secret to delectable fried dishes is fresh and hot serving. Any delay causes the finished products to lose their crispiness. Preparing your menus in your kitchen and delivering them at the event venue takes away the joy and flavor of fried foods. Therefore, on-site caterers should benefit from single or double-tank outdoor fryers.

Business Type – Restaurant Fryer Match

By considering all the needs of your business and information about fryers, you can find the best restaurant fryer for your establishment. Small facilities with restricted floor space can benefit from the countertop fryers. If you’re mainly serving french fries, a single-pot configuration is ok. Yet, split-pot works better if you have several different fried items on the menu. A ventless fryer would work well in a school cafeteria, office breakroom, or a historical building where traditional ductwork isn’t feasible or permissible.

Quick-serve restaurants, catering kitchens, hotels, or fast-food chains will need freestanding restaurant fryers to handle high-volume demands. Full-serve restaurants with diverse menu items will require a multiple-battery unit to make their customers happy without flavor transfer between different fried dishes. The onboard oil filtration and auto basket lift features can make a massive difference if you have unexpected business peaks.

Additional Accessories

Besides a high-quality restaurant fryer, you’ll need some cooking and maintenance accessories to improve your workflow and design an effective frying line. You might need to check if your purchase includes the following tools. Even so, it is advisable to store some extras, especially if fried meals are the staples of your restaurant.

- Fryer Baskets: You need these wire baskets to safely lower products into the hot oil tank. They come in various sizes and shapes. Standard restaurant fryers use rectangular or square fryer baskets. For specialty items, you can prefer tostada baskets, taco shell baskets, or taco salad bowl makers. You can fry portions separately with a portion control basket and serve fresher dishes.

- Fryer Screens/Crumb Screens: These mesh wires are placed below the frying area to collect the tiny food particles dropping off the fryer basket. They help you keep the bottom of the tank clean and prolong the oil lifespan.

- Fry Dump Stations: Fried products can lose crispiness the longer the oil cools inside the item. You can add a fry dump station – a heated cabinet – to your restaurant fryer to keep finished products hot at serving temperatures.

- Bread And Batter Stations: Seasoning ingredients before they’re deep-fried causes a significant mess in commercial kitchens. You can develop a more efficient frying line with these portable worktables featuring separate pans and baskets for batter and breading mixtures.

- Oil Filtration Supplies: If you don’t opt for a restaurant fryer with an onboard oil filtration system, you can consider buying a mobile fryer filter machine. These automatic systems remove the labor and risks involved in manual filtering. You might also need replacement filter papers, filter powders, and liquids to extend oil life and oil test kits to know the exact time for an oil change. When your test kit tells you it’s the time, you can dump the used oil from your deep fryers into an oil caddy and roll it into a disposal container.

FAQs Of Restaurant Fryers

1. How Much Does A Restaurant Deep Fryer Cost?

It is hard to say a set price. Prices might extend from 250-300 dollars on countertop models to over 100 thousand on multiple-battery units.

2. Do You Have To Use A Basket In The Deep Fryer?

No, especially for home cooks. However, commercial settings are fast-paced environments. You’ll need some equipment like a scoop to load the items into the oil tank. Fryer baskets can help operators handle the process safely and without much delay.

3. What Kind Of Fryers Do Food Trucks Use?

Depending on space, they can use a countertop or floor restaurant fryer. With greaseless versatile cooking capacity, Quick n Crispy air fryers can also be profitable alternatives for food trucks.

4. Do I Need A Hood For An Electric Fryer?

Yes. All commercial deep fryers – electric or gas – must be under a Type I hood. If your building structure isn’t suitable or requires remodification to install a hood, you can consider buying a ventless fryer.

5. What Is The Best Oil For Deep-Frying?

Vegetables, canola, corn, and peanut are the most popular types. Three points are central to choosing the best oil. It should be cheap enough, have a neutral taste, and withstand high frying temperatures. While vegetable oil is the winner in the first two, peanut oil is unrivaled in the third with the highest smoke point of 450°F.

6. How Often Should Restaurant Fryer Oil Be Changed?

It depends on what you fry and how often. Used oil can cause health hazards and decrease taste quality. If you want to be on the safe side, you can get an oil test kit to know when exactly you should change the oil.

Conclusion

Deep-frying is one of the quickest, most widespread, and most efficient cooking ways, adding a crispy and succulent texture profile to battered or breaded products. Restaurant fryers can prepare entrees, side dishes, snacks, desserts, and main courses. Therefore, they’re one of the primary income drivers in restaurants, cafeterias, food trucks, burger joints, fast-food chains, bars, and even coffee shops. That’s why roughly 85% of commercial kitchens in America have at least one fryer. So, why not be one of these?

2 comments On A Step-By-Step Guide To Buying A Restaurant Fryer

Pingback: Fast Food Restaurant Equipment ()

Pingback: Celebrate National French Fry Day - Chef's Deal ()