Refrigerated prep tables are multifunctional commercial refrigeration units that combine food prep space with refrigerated storage in a seamless design. They keep ingredients at proper temperatures, maintaining food safety and preventing bacteria growth. Chefs assemble pizzas, salads, or other dishes faster with all the ingredients and tools readily accessible next to the prep surface.

Refrigerated prep tables serve as a cornerstone in the operational efficiency of commercial kitchens, blending crucial refrigeration with a versatile work surface to streamline food preparation processes. These tables feature a sophisticated refrigeration unit that ensures ingredients are kept at optimal temperatures, typically ranging from 33°F to 41°F (0.55 °C to 5 °C). A durable stainless steel work surface stands up to daily kitchen demands, while a removable polyethylene cutting board offers a hygienic platform for food prep tasks.

The inclusion of a food pan area allows for organized and quick access to ingredients, and built-in storage compartments maximize the utility of the workspace. Insulated lids and hoods help maintain internal temperatures and improve energy efficiency. Advanced digital temperature controls provide precision, with high-quality insulation and airtight gaskets reinforcing temperature consistency and energy savings. Adjustable shelves and racks within storage compartments afford customizable organization options. A key to their functionality, the ventilation system efficiently expels heat, ensuring the unit’s effectiveness.

Available in various configurations, from sandwich and pizza prep tables to specialized options for seafood and bakeries, choosing the right refrigerated prep table involves considering food prep tasks, kitchen space, storage requirements, and budget. Selecting a model tailored to specific needs not only enhances workflow and food safety but contributes significantly to the kitchen’s overall efficiency.

What are The Main Features of Refrigerated Prep Tables?

The main features of refrigerated prep tables are:

- Temperature Control

- Work Surface

- Storage Capacity

- Power

- Self-Contained Refrigeration System

- Mobility

- Ingredient Pan Compatibility

- Easy Cleaning

- Energy-Efficiency

- Warranty

- Brand

Refrigerated prep tables have digital temperature controls for food safety, a durable stainless steel worktop for easy cleaning, and a refrigerated base to keep ingredients close at hand. Helpful extras like energy-efficient models, removable cutting boards, casters for mobility, self-closing doors, and anti-bacterial work surfaces make refrigerated prep tables truly versatile and resourceful kitchen equipment. Check the following main features of refrigerated prep tables carefully to optimize food prep and storage.

Temperature Control

The temperature control system keep ingredients within 33°F – 38°F (0.55°C – 3.33°C), 33°F – 40°F (0.55°C – 4.4°C), or 33°F – 41°F (0.55°C to 5°C). Precise adjustments within these ranges and consistent temperatures are essential. Refrigerated prep tables ensure this in 3 ways:

- Adjustable temperature ranges enable you to tailor the storage environment specifically for different ingredients. Meat and poultry require temperatures closer to 33°F (0.55°C) to prevent bacterial growth, while fruit and vegetables remain fresh and safe from chilling damage at around 41°F (5°C).

- Digital thermostats with easy-to-read LED displays provide superior precision in temperature control. They clearly show the current temperature, allowing quick adjustments and minimizing the risk of foodborne illnesses.

- Refrigerated prep tables have fans that circulate cool air to ensure a consistent temperature across the whole unit. This uniformity avoids temperature fluctuations within the cabinet.

What Temperature Is Ideal For Refrigerated Prep Tables?

The ideal temperature for refrigerated prep tables is 33°F – 41°F (0.55°C to 5°C), based on the NSF/ANSI 7 guideline. This range offers greater flexibility in customizing temperatures by ingredients.

Work Surface

A refrigerated prep table needs a sturdy work surface for a reliable and long-lasting performance because chopping, mixing, and all other food-prepping tasks happen on the working counter. It must withstand the rigors of a busy kitchen, from the constant knife pounds to frequent cleaning routines. The industry standard for work surface material is stainless steel. It reigns supreme for 3 reasons:

- Stainless steel is exceptionally durable and able to handle heavy equipment, sharp utensils, and cleaning tasks without chipping, cracking, or warping under pressure.

- The smooth, non-porous surface of stainless steel is sanitary, easy to clean, and leaves no crevices for bacteria to hide.

- Stainless steel is highly resistant to corrosion caused by condensation, cleaning, or wet ingredients.

Size and configuration are other critical considerations when selecting your refrigerated prep table’s work surface. This is the area where you chop greens for salads, slice onions for sandwiches, or chop vegetables for pizza toppings. Try to align the length and depth of the work surface with your workflow needs. A full-length removable cutting board made from NSF-approved materials minimizes cross-contamination. Some units even integrate a prep sink into the work surface to streamline workflow.

Storage Capacity

The storage capacity of a refrigerated prep table, measured in cubic feet, specifies the internal volume of the refrigerated compartments. Capacities range from 6 cu ft (169.90 L) to over 50 cu ft (1415.84 L). This space allows you to keep ingredients readily accessible at safe temperatures. Remember that increased capacity means a larger size, so target a balance between efficient space use and meeting your daily volume needs. Storage is not just about internal volume but about the internal organization. Consider the 3 features below to improve the organization of the storage space.

- Drawers and Cabinets: Refrigerated prep tables offer drawers or cabinets beneath the worktop, ideal for storing ingredients and utensils. They make your work surface clutter-free. Prep tables often have 1 to 4 sections configured with 1 to 4 doors, 2 to 8 drawers, or a combination of the two.

- Adjustable Shelves: Some models have adjustable shelves to provide flexibility. They enable you to customize the storage space to accommodate tall containers or bulk ingredients and place smaller items on lower shelves, enhancing storage capacity.

- Overhead Storage: Refrigerated prep tables with overhead compartments are perfect for storing frequently used items like sauces, condiments, or garnishes within easy reach.

Power

Refrigerated prep tables use compressors with motor ratings spanning from 1/8 to 3/4 HP. A higher HP rating means a more powerful compressor. During peak times, you frequently open the prep table doors and load large batches of warm ingredients, which causes temperature fluctuations. A more powerful compressor quickly recovers from such fluctuations and maintains consistent cool temperatures.

1/8 to 1/2 HP motors are suitable for smaller prep tables in low-volume kitchens. 3/4 HP motors are ideal for larger units with a capacity of 20 cu ft (566.337 L) and over. They provide faster cooling times and superior temperature stability, ensuring food safety during peak hours. Note that HP isn’t the only factor in temperature control; insulation quality and ambient temperatures are crucial. Your HP selection depends on the unit’s size, the expected volume of use, and your budget.

Self-Contained Refrigeration System

The self-contained system in refrigerated prep tables contains all the refrigeration components in a space-saving design at the bottom rear or side of the prep table. There is no need for separate compressors, condensers, or complex refrigerant lines. This compact and integrated system makes refrigerated prep tables plug-and-play appliances. After locating and leveling your unit, connect it to a standard electrical outlet, and there you go! There is no need to hire a professional for installation.

Mobility

Refrigerated prep tables come equipped with caster wheels, making them mobile workstations. These wheels are convenient for easy cleaning and layout flexibility. During cleaning routines, roll the prep table away from the wall and access all sides for a thorough wipe-down. Refrigerated prep table wheels let you reposition the table within your kitchen. Thus, you can adapt your layout quickly to accommodate different workflow adjustments.

Ingredient Pan Compatibility

Refrigerated prep tables feature a pan rail that holds multiple pans for pizza toppings, salad ingredients, and other garnishes or condiments. The slots in the rail are compatible with different ingredient pans, from full-size to 1/6-size pans. They accommodate 4 to 18 third-size fractional pans. Choosing a prep table with compatible pan sizes ensures a smooth workflow and flexibility. Pans that perfectly fit the pan rail maximize storage capacity and minimize the risk of spills or ingredients overflowing during storage or transport.

Easy Cleaning

Maintaining a sanitary workspace is critical for commercial kitchens, and refrigerated prep tables boast effortless cleaning. Cleaning ease saves you a lot of time and labor in your operations. So, look for the following features:

- Smooth stainless steel surfaces of refrigerated prep tables resist grime buildup and wipe down easily.

- Rounded corners eliminate crevices where bacteria can hide.

- Removable components like drawers, shelves, and cutting boards facilitate thorough cleaning.

- Refrigerated prep tables with accessible drain systems allow easy removal of the condensation water.

- Certain high-end models have antimicrobial surfaces to promote a more hygienic environment.

Energy Efficiency

Energy efficiency is a primary consideration for any commercial kitchen appliance. When buying refrigerated prep tables, prioritize features like thicker insulation or high-performance compressors. The easiest way to find energy-efficient models is to look for the prestigious Energy Star certification. These models consume up to 40% less energy than standard ones, saving you hundreds of dollars annually on energy use alone. These cost savings further increase as Energy Star certification sharpens your brand image. Energy Star-rated prep tables are eligible for instant rebates.

Warranty

A strong warranty is a permanent protective shell for your investment, so check the warranty length and coverage when purchasing your refrigerated prep table. Warranty length indicates the manufacturer’s confidence in the product’s durability. A warranty that covers both parts and labor protects you against component failures and repair costs. Many manufacturers offer additional warranties on compressors. Typical warranties in the market range from 1 to 3 years on parts & labor and 5 to 7 years on compressors.

Brand

Investing in a refrigerated prep table brand renowned for quality and reliable customer service goes beyond all these features; it ensures you get a durable, dependable, and functional prep table that withstands the rigors of busy commercial settings. The established brands’ commitment to quality means less downtime and a lower cost of ownership. In case of an issue, their exceptionally supportive customer service responds to you promptly. You can choose one of the popular refrigerated prep table manufacturers in the list below:

- Adcraft

- Akita

- Arctic Air

- Asber

- Atosa USA

- Beverage-Air

- Bison Refrig

- Blue Air

- Centerline by Traulsen

- Continental Refrigerator

- Culitek

- Delfield

- Dokers Appliance Co.

- Everest Refrigeration

- Fagor

- Grista

- Hoshizaki

- IKON

- Kelvinator

- Kool-It

- Marra Forni

- Maxx Cold

- Migali

- Montague Company

- Narpole

- Omcan USA

- Pro-Kold

- Randell

- RefrigerationX

- Serv-Ware

- Silver King

- Spartan Refrig

- Tarrison

- Traulsen

- True

- Turbo Air

- U-Line

- USR Brands

- U-Star

- Valpro

- Victory

What are The Main Parts of Refrigerated Prep Tables

A refrigerated prep table mainly consists of the following parts:

- Refrigeration Unit

- Working Surface

- Cutting Board

- Food Pan Area

- Storage Compartments

- Lid/hood

- Temperature Control

- Insulation

- Gaskets

- Shelves and Racks

- Ventilation system

Prep tables have a top and bottom component. The top includes a spacious working surface, a removable cutting board, and a food pan area often covered with a lid. The bottom houses the storage compartments with shelves and racks. Insulation and gaskets around the doors and drawers of the storage compartments help contain cold air. The self-contained refrigeration unit and the ventilation system help keep the unit at desired cold temperatures, easily regulated with a digital thermostat.

Refrigeration Unit

The refrigeration unit maintains cold temperatures to keep ingredients fresh. This part is the heart of the prep table. This self-contained system has a 1/8 to 3/4 HP compressor motor that circulates cool air to maintain a safe and consistent temperature for the stored items. It includes a condenser, evaporator coil, and expansion valve, which work together to remove the heat from the interior. The 2 common refrigerants used in the system are R134A and R290. The hydrocarbon R290 refrigerant is more eco-friendly and energy-efficient.

Working Surface

The working surface is the stainless steel countertop where all the food prep tasks happen. It provides a durable and easy-to-clean platform for chopping vegetables, mixing ingredients, kneading dough, rolling out a pizza base, or assembling dishes. Its width ranges from 27 in (69.39 cm) to 119 in (305.83 cm).

Cutting Board

A refrigerated cutting board is a removable board that enables a safe and hygienic surface for cutting and chopping ingredients. It provides a dedicated area for chopping and preparing food. It is typically made from NSF-approved polyethylene, known for its resistance to warping or cracking and ease of cleaning. They mostly cover the full width of the refrigerated prep table and the depth of the work surface, which is often between 10 in (25.4 cm) and 24 in (60.96 cm). Some models offer reversible cutting boards for added convenience.

Food Pan Area

The food pan area is designated slots or spaces on the table’s surface to hold food pans, which are used to store and organize ingredients for easy access. It is crucial for efficient ingredient organization. The design facilitates and accelerates dish assembly. With adjustable dividers or pan adapters, it accepts different-sized pans. The pan capacities can go up to 18 third-size or 36 sixth-size pans. The depth of the food pan area usually aligns with the standard steam table depth of 6 in (15.24 cm).

Storage Compartments

Storage compartments are built-in spaces (in the form of cabinets or drawers) below the working surface for storing utensils, additional ingredients, and other necessary items. Refrigerated tables have 1 to 4 compartments beneath the work surface. Some models combine the two for a more flexible storage organization. The cabinets often have self-closing doors with a stay-open feature. The drawers allow storing items in standard food pans.

Lid/Hood

The lid/hood covers the food pan area, helping to maintain temperatures and protect ingredients from contamination. Most refrigerated prep tables feature an insulated lift-up or hinged lid or hood that covers the food pan area. This cover reduces the escape of cold air and keeps the ingredients safe from airborne contaminants, improving energy efficiency and sanitation. Units with transparent lids enable servers and customers to see the contents without opening the cover.

Temperature Control

The temperature control system is a digital thermostat that allows you to track and set precise adjustments in the refrigerated prep table’s internal temperature. The LED display provides an easily visible readout. Common temperate ranges typically fall between 33°F and 41°F (0.55°C and 5°C). The ideal temperature is around 38°F (3.33°C) as it prevents bacteria growth and maintains optimal freshness for your ingredients.

Insulation

Refrigerated prep tables use high-quality insulation materials like polyurethane foam around the entire cabinet, doors, drawers, and lids. The insulation helps keep cold air inside and hot air outside, minimizing heat transfer. This heat retention enhances food safety and lowers energy consumption.

The thickness of insulation in refrigerated prep tables typically ranges from 1 to 2 in (2.54 to 5.08 cm). This thickness is chosen to provide effective thermal resistance without excessively increasing the size of the unit. The exact thickness can vary depending on the manufacturer’s design and the specific model’s intended use or energy efficiency standards.

Gaskets

Gaskets are seals around the doors, drawers, and lid. They create an airtight barrier, trapping cold air inside and improving energy efficiency. The magnetic gaskets are removable without tools for easy cleaning.

Shelves and Racks

Adjustable shelves and racks inside the storage cabinets provide flexibility in organization. The heavy-duty wire shelves are often adjustable at 0.5-in (1.25 cm) increments, so you can customize the layout depending on the sizes of the stored items.

Ventilation System

The refrigeration unit generates heat during operation. The ventilation system uses fans and vents to expel this hot air to the surrounding environment, enhancing condenser efficiency. The placement of the self-contained refrigeration system relates to the ventilation system. Front-mounted systems have front-breathing compressors, and rear-mounted systems have rear or side-breathing compressors. The ideal system to choose depends on your kitchen layout. In space-tight kitchens, front-breathing is a space-saving option as it allows placing the refrigerated prep table directly against the wall without any clearance.

Construction Material of Refrigerated Prep Tables

Refrigerated prep tables are constructed from stainless steel, which is incredibly tough and withstands frequent use in commercial environments. Its smooth surface makes cleaning a breeze. Stainless steel has a sleek look, complementing any kitchen concept. Its thickness is measured in a gauge system. Manufacturers generally use 14-gauge (2.03 mm) to 22-gauge (0.71 mm) stainless steel in prep tables. The lower the gauge, the thicker and stronger the metal sheet. Some brands use different gauges for different parts, such as 18-gauge (1.22 mm) for the top and 22-gauge (0.71 mm) for the sides.

What are The Cooling System Types of Refrigerated Prep Tables?

Refrigerated prep tables use forced air and cold wall cooling systems to maintain safe and consistent temperatures for the ingredients.

Forced Air Cooling

This system circulates cold air throughout the refrigerated components. The air passes over the evaporator coil chilled by the refrigerant, absorbs the coolness, and is forced across the refrigerated prep table. Forced air cooling is generally more affordable and has a simpler design.

Cold Wall Cooling

Cold wall cooling relies on conduction instead of forced air circulation. The refrigerated prep table’s interior panels contain a circulating coolant chilled by the refrigerant. It conducts the coolness to the food pans and other refrigerated parts. This system is more energy-efficient and offers greater temperature consistency.

Maintenance of Refrigerated Prep Tables

Maintaining your refrigerated prep table boosts performance, hygiene, and longevity. Daily tasks include wiping down surfaces with warm, soapy water or food-grade sanitizer. Routine upkeep increases the value of your investment. Use the following guidelines, but always refer to the manufacturer’s manual for more complete servicing.

- Take out the removable parts like the cutting board, gaskets, drawers, and shelves for a more thorough cleaning.

- Clean the dust buildup on condenser coils with a soft brush or vacuum cleaner.

- Regularly inspect the internal temperatures with a calibrated thermometer.

- Check the gaskets for wear and damage and replace them when necessary.

- Schedule professional maintenance at least annually to identify potential issues and prevent downtime.

What are The Types of Refrigerated Prep Tables?

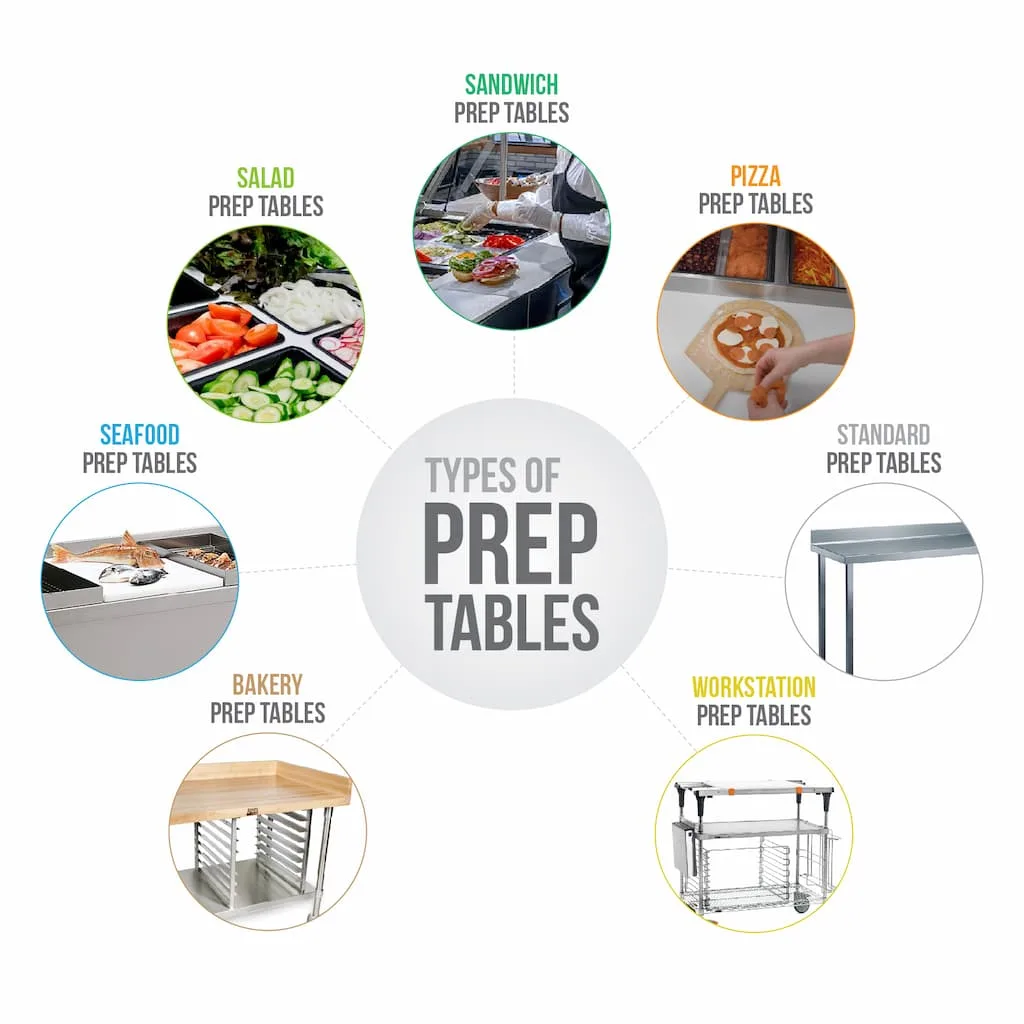

Refrigerated prep table types are:

- Sandwich Prep Tables

- Pizza Prep Tables

- Salad Prep Tables

- Seafood Prep Tables

- Bakery Prep Tables

- Workstation Prep Tables

- Standard Prep Tables

The core function of refrigerated prep tables is to combine refrigerated storage and a work surface. Their types are based on the configuration of the storage compartments and the work surface to suit specific workflows and food prep needs. Choosing the right table refines your operations and maximizes performance.

Sandwich Prep Tables

Sandwich prep tables are used for large-volume sandwich assembly in busy delis, cafes, fast-food outlets, or restaurants with a high demand for sandwiches. They have ingredient wells located at the same level as their shallow cutting board area. The wells usually accommodate 1/6-size pans for frequently used ingredients, such as sliced meats, vegetables, and cheeses. The cabinets or drawers under the work surface help store other food items, buns, and prep tools.

Pizza Prep Tables

Pizza prep tables are the workhorses of pizzerias. They provide a tough surface for dough rolling, a spacious working space for topping assembly, and deep ingredient wells for storing prepped toppings. The pizza prep tables’ pan area is slightly raised to free enough space for the work surface to accept the diameter of a pizza. The drawers or cabinets beneath are perfect for keeping pizza boxes, dough trays, prepped pizzas, and utensils.

What are The Difference Between Sandwich and Pizza Prep Tables?

The main difference between sandwich and pizza prep tables is their sizes. Pizza prep tables feature a wider working surface. The raised pan rail configuration gives chefs a larger counter space to shape the dough. The overall width differs between these prep tables. Sandwich prep tables are usually around 18 in (45.72 cm) to 94 in (238.76 cm) wide, while pizza prep tables’ widths span up to 119 in (302.26 cm).

Salad Prep Tables

Salad prep tables offer a comfortable working surface for chopping and mixing vegetables. They present a more flexible food pan configuration to accept different pan sizes: wells for standard food pans to hold large ingredients like lettuce or chopped vegetables and wells for shallower pans to hold dressings.

Seafood Prep Tables

Seafood prep tables are specifically designed for handling, preparation, and storage of seafood in commercial kitchens and seafood markets. These specialty prep tables have chilled compartments to keep seafood at safe, fresh temperatures and surfaces that are easy to clean and resistant to corrosion from saltwater and moisture. They usually feature drainboards on one or both sides, a dump hole, and a sprayer.

Refrigerated Bakery Prep Tables

Refrigerated bakery prep tables offer a much larger counter space for dough rolling, shaping, decorating, and assembling baked products. The durable and cool work surface withstands the dough kneading pounds and prevents the dough from sticking. Some models of these specialty prep tables have built-in dough bowls, flour bins, and proofing drawers for added convenience.

Refrigerated Workstation Prep Tables

Refrigerated workstation prep tables are specialized equipment designed for culinary environments that combine a refrigeration unit with a work surface to facilitate food preparation. These tables feature an integrated cooling system that maintains perishable ingredients at safe temperatures right at the workstation. Workstation prep tables have a modular design. The work surface, shelves, drawers, and other storage compartments are customizable, enabling you to configure an all-inclusive workstation catering to your unique workflow. Many models incorporate overhead shelves. They are a combination of a prep table with a handwashing sink and a waste disposal unit for a consolidated workspace.

Standard Refrigerated Prep Tables

Standard refrigerated prep tables have the same functionality as the other types. Their top configuration is standard, often with 2 rows of ingredient wells and 10 in (25.4 cm) to 15 in (38.1 cm) deep cutting boards.

How To Choose Refrigerated Prep Table

Buying the ideal prep table requires certain considerations, including your space constraints, food prep tasks, and budget. Evaluate each of the following points carefully:

- Consider Your Primary Food Prep Tasks: Do your guests primarily prefer you for your delicious pizzas, sandwiches, salads, pastries, or delicate seafood? A standard prep table accommodates many prep tasks, but special recipes require specialty prep tables.

- Evaluate Your Space Constraints: Measure the available space in your kitchen before diving into different models. Locate the place to install the refrigerated prep table, consider clearance, and then match the right size. Try not to cram your kitchen and impede traffic flow.

- Think About Storage Needs: Consider the volume and type of ingredients you use to decide how many ingredient wells you need in the food pan area. Choose the right door, drawer, and shelf configuration for the base depending on the other items you need to store in a refrigerated environment.

- Prioritize Features: Identify features that significantly improve your workflow efficiency. Is cold wall or forced air cooling better for you? Opt for a front-breathing compressor if your space doesn’t allow for enough clearance. Check extra options like sneeze guards or clear lids.

- Evaluate Your Budget: Set a realistic budget that covers the initial purchase, any installation expenses, and the long-term cost of ownership. Refrigerated prep tables with energy-saving features and additional functions come with a higher price tag, but they are worthier as they reduce utility bills, enhance workflow, and increase output.

- Get Professional Consultation: Consider seeking advice from professional equipment specialists. They provide valuable insights about specific kitchen layouts, design, and financing.

Conclusion

Workflow efficiency is a top priority in commercial kitchens, and refrigerated prep tables are crucial in making kitchen tasks flow efficiently. They are all-in-one kitchen solutions combining a spacious prep surface with dedicated top and bottom refrigerated storage. They maintain food safety and accelerate dish assembly by keeping everything within arm’s reach in a mobile design. You have many size options to meet diverse capacity and space requirements. Refrigerated prep tables are available in various types, from sandwich and salad tables to pizza and seafood tables, to address unique food prep tasks.