Whether you’re a business owner, manager, or simply curious about walk-in refrigeration, explore our compilation of frequently asked questions to gain valuable insights on walk-in refrigerators and freezers. You can find out more about optimizing performance, energy efficiency, and maintenance of these essential cold storage units. Discover key aspects and expert advice to make informed decisions regarding walk-in refrigeration solutions.

1. What is Walk-in Refrigeration?

Walk-in refrigerators and freezers are large, heavily insulated capacity solutions for commercial settings such as restaurants, hotel kitchens, and even florists. They are used to store perishable products such as flowers, frozen foods, and more. Walk-in refrigerations are designed like small storage rooms with lots of shelves that can be easily navigated and used for organized storage purposes.

2. What are the Initial Investment Costs for Installing a Walk-in Refrigeration?

The initial investment costs for installing walk-in refrigeration depend on the size, brand, and model of the unit, as well as the installation costs, delivery, warranty period, and customization choices.

- Price of the Unit: The base price of the unit is the most sizable and fixed upfront cost for installing a walk-in refrigeration. The price of the unit depends on the brand, size, capacity, material, and technological features of the model. You can find smaller models for as low as $6,000, but on average, expect to pay $15,000 to $20,000 for a reliable unit that can meet the demands of a medium to large establishment.

- Size: If you opt for a bigger model, you will inevitably pay more for the extra square feet of space. Also, if you are investing in a significantly bigger model, expect to pay more on delivery and installation, too, since size defines the amount of machinery and people needed for these steps.

- Delivery: Since walk-in refrigerations tend to be massive, they are often manufactured upon order and delivered with the help of a crane. Shipping prices might spike depending on the size and the weight of the walk-in and also the distance between your supplier and your business.

- Installation: Installing walk-in refrigerators and freezers can cost between $2,000 and $4,000. The price depends on whether infrastructural work, such as extra electricity, water, and ventilation modifications and integration, is needed and how many professionals are needed for the installation stage. If your unit is a custom-sized model that requires a lot of infrastructural work, you can expect the price to go as high as $10,000 since wiring and plumbing are all extra spending areas.

- Customizations and Accessories: You can customize the size, floors, the number and size of shelves and racks, the type of doors, and more when buying a walk-in unit. Also, you can invest in add-on accessories such as remote monitoring systems. Such modifications will raise the price.

All these considerations serve to raise the initial investment costs. On average, you can expect to pay as low as $10,000 and as high as 50,000 $ for everything combined.

You can find a comprehensive guide to purchasing walks in our article “26 Key Factors When Buying Walk-ins.”

3. Which Factors Affect the Walk-in Operating Cost?

4 considerations listed below affect the walk-in operating costs:

- Insulation: A well-insulated walk-in’s operating costs will be lower since the energy is being efficiently used and the generated cool air is safely trapped within the unit. Proper insulation can save you up to %42 percent of energy.

- Energy efficiency: Investing in an energy-efficient model early on can save you money in the long run. Energy efficiency can be achieved through the use of motion-detecting LED lights, thickly insulated panels, use of efficient refrigerants, and more.

- Placement: The placement of the unit within your kitchen plays a role in its efficiency. Make sure to place the walk-in away from heat-generating machines such as ovens to avoid counteracting its efforts.

- Climate: If you live in a particularly warm area, your unit might need to use more energy to achieve and maintain the desired temperatures. A good ventilation and air conditioning system can help neutralize the impact of climate change on your energy bills.

4. Are There Any Incentives or Rebates Available for Investing in Energy-efficient Walk-in Refrigeration?

Yes, there are incentives and rebates available for investing in energy-efficient walk-in refrigeration. You can also follow dealers’ and manufacturers’ campaigns to benefit from instant rebates, tax reductions, or discounts for energy-efficient models over other options.

5. What Financing Plans are Available for Purchasing a Walk-in, and How Do They Affect the Overall Cost?

You can receive equipment financing from lenders such as PEAC Solutions, Click Lease, Approve, Credit Key, Navitas Credit Corp., Quickspark, Middleby, and Welbilt. The financing maximum limits can range from $20,000 to no upper limit. Most financing plans commonly include the following features, and you can research the lenders from our financing service to find the best one for you:

- All credit scores are welcome

- Easy application and fast approval

- Tax benefits and deductions

- Payment terms of 12 to 72 months, depending on your individual plan

- Warranty and service fees such as shipment and installation can also be covered through equipment financing.

6. What are the Size Options for Walk-ins?

The size options for walk-ins tend to be as follows:

- 6’x8’ (1.82 x 2.44 m)

- 6’x10’ (1.82 x 3.05 m)

- 6’x6’ (1.82 x 1.82 m)

- 8’x8’ (2.44 x 2.44 m)

- 10’x8’ (3.05 x 2.44 m)

- 10’x10’ (3.05 x 3.05 m)

- 10’x12’ (3.05 x 3.65 m)

- 12’x12’ (3.65 x 3.65 m)

While these size options are the most standard and popular, you don’t need to restrain yourself to these measurements. You can customize the height, length, width, and depth of your unit with the help of your manufacturer. However, keep in mind that custom-sized units will take longer to be manufactured and delivered.

7. How Do I Choose the Right Size for My Walk-in, Considering Space, Usage, and Product Types?

You can choose the right size for your walk-in by assessing the size and shape of your space, what will be stored in it, and how much capacity you will need.

- Size and Shape of The Space: If the area you allocated for the unit is indoors and limited, you will need to limit the size of your walk-in to the available space. You can add reach-in models for support and easy daily use if your space doesn’t allow for a large unit. If the shape of the area is odd, you can talk to your dealer for a custom-sized model to navigate the space and maximize your usage.

- Usage: Storage demand is the primary defining factor of walk-in purchases. Monitor your bulk purchases to see how much capacity you really need.

- Product types: The type of product you wish to store in the walk-in can help you with your decision. For example, if you will store short and small items, instead of increasing the square footage of your walk-in you can customize the number of shelves within to use the space more efficiently.

8. What Technologies are Typically Used in Walk-in Refrigeration?

Technologies such as self-closing doors, LED lighting, monitoring and alarm systems, thermostats, fans for circulation, and refrigerants for cooling effects are typically used in walk-in refrigeration. Each technological component contributes to the functioning and long-term efficiency of the unit in different ways. Self-closing doors and motion sensor LED lights can save you a lot of energy, and monitoring systems, whether for security or temperature, can alert you in a timely fashion in case of emergencies. Fans and refrigerant use are more deep-set within the mechanism of a walk-in. While fans are responsible for circulating the air and dispatching heat from the machine as much as possible, refrigerants are the cooling agents used in refrigeration units.

9. How is Temperature Control Managed in Walk-ins?

Temperature control in walk-ins is managed through thermostats. Thermostats sense the temperature of the unit and trigger the refrigeration mechanism if it is below the desired temperature. Once the system is triggered, several components, such as compressors, condensers, evaporators, and expansion valves, come into play to achieve a cooling effect. Once the heat is removed and the unit is properly cooled, the thermostat interrupts the system and ends the cycle till it is necessary again.

10. What are the Best Practices for Maintaining Optimal Temperatures?

The best practices for maintaining optimal temperatures in walk-in refrigeration are as follows:

- Monitor the Temperature: You can either manually note the unit’s temperature at certain intervals or invest in an electronic monitoring system to better document the unit’s temperatures. Electronic systems can be paired with your smartphone and offer easy access to data remotely while notifying you of any fluctuations or mishaps in real-time.

- Door Seals and Self-Closing Doors: Check for air leaks in your unit. Door seals can become damaged over time, so include a check-up in your maintenance schedule. You can also invest in self-closing doors to prevent heat loss due to staff forgetfulness.

- Calibrate the Thermostat: The thermostat is an important agent in the cooling cycle, and its periodical calibration will ensure that the cooling cycle is triggered and interrupted at the right times.

11. What are the Installation Requirements for Walk-in Refrigeration?

The installation requirements for walk-in refrigeration are as follows:

- Ceiling and Wall Clearances: You should leave a minimum of 2” space on each side, including the ceiling, to allow for proper ventilation. You can leave extra room at the top for ease of maintenance, especially for top-mounted models.

- Level Floor Surface: Make sure the floor is level before installing the unit. Whether it is a floored model or not, without a level surface, you risk air leaks and make the installation process more prone to mistakes.

- Drainage: You should have a drainage within the walk-in to create an easily cleanable space.

You should check your local guidelines and regulations to learn about your area’s special requirements and circumstances.

12. What are Common Challenges When Installing a Walk-in?

The common challenges when installing a walk-in can include the following:

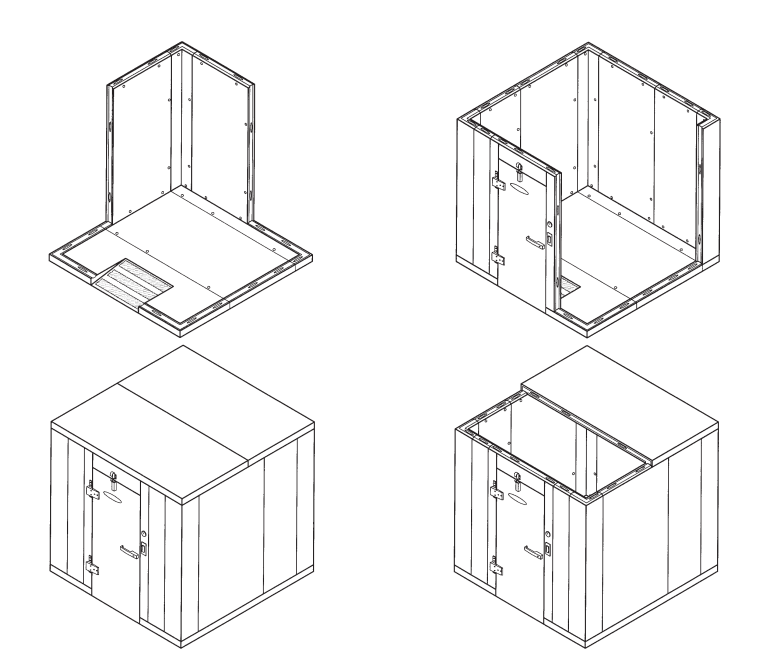

- Transportation: Transporting the unit is the biggest challenge when installing a new walk-in. Due to their large size, they are hard to carry and even harder to pass through door frames. You might need to assemble most of the walk-ins within the allocated space to bypass the issue of narrow door frames and potential damage to the machinery during transportation.

- Uneven Floors: Uneven floors, whether for outdoor walk-in fridges or indoor machines, threaten the structural integrity of the whole machine. This issue should be resolved before the installation to avoid misaligned assemblies and potential air leaks.

- Insufficient Electricity: Walk-in refrigerators and freezers work constantly and demand a certain amount of electricity regularly. Make sure that your electricity output is good enough to support these pieces of equipment.

- Leveling and Alignment of Panels: Walk-in refrigeration that is assembled on-site requires a professional touch for proper alignment and leveling. If the unit isn’t pieced together carefully, the panels might end up misaligned and lose their insulation function by allowing air to wander in and out.

13. What are the Key Features of Energy Efficiency in Walk-ins?

The key features for energy efficiency in walk-ins can be summed up as follows:

- R-Value of the Insulation: R-value refers to the quality of the insulation layer. A high R-value insulation minimizes heat transfer, reducing the workload on the refrigeration system and lowering energy consumption.

- Door Seals: Well-maintained door seals prevent air leakage, keeping cold air inside and reducing the need for the refrigeration system to work harder to maintain temperature.

- Self-closing Doors: Self-closing doors close automatically after being opened. This prevents accidental prolonged openings due to forgetting and such and minimizes air escape.

- LED Lights: LED lights consume significantly less energy than their counterparts and don’t generate a lot of heat. These features lighten the system’s cooling load.

- Motion-Censored Lights: Motion-censored lights activate only when needed, reducing energy consumption by ensuring that lights are not left on unnecessarily when the walk-in is not in use.

14. How can Energy Features of Walk-ins Save on Long-term Costs and Contribute to the Environmental Impact?

Energy features of walk-in can reduce long-term costs significantly and lower your carbon footprint as a business. Minimizing wasteful use will lower your utility bills, and you will have reduced your environmental impact by using a single unit for as long as you can and reducing your greenhouse gas emissions associated with energy generation and such.

15. What is the Average Lifespan of a Walk-in?

The average lifespan of a walk-in is around 15 years. If the unit is well-maintained and taken care of, you can expect it to work without a hitch for longer.

16. Can Walk-in Refrigeration be Custom-sized?

Yes, the walk-in refrigerators and freezers can be custom-sized. You can talk to your supplier to decide on the dimensions and get a custom model for your special circumstances.

17. What are the Walk-in Weight and Material Specifications?

The weight of a walk-in depends on the material used in its construction, the size of the unit, the thickness of the insulation, and the amount of accessorial materials such as shelves and racks. While the weight of the cooler is usually included on the product’s webpage, if you are purchasing a custom model, you can guesstimate its weight based on the following information: the typical weight of wall and ceiling panels averages 2.4 lbs per square foot (1.09 kg per sq. meter), while floors weigh approximately 3.9 lbs per sq. ft. (1.77 kg per square meter). Additionally, the standard door has a weight of 165 lbs (74.8 kg).

In terms of material, the most commonly used panel materials are stainless steel, aluminum, and galvanized steel on some occasions. Panels are made up of two metal sheets with an insulation layer between them. All three layers combined usually add up to 7.5” to 9” (11 cm to 22 cm) thickness. The thickness of the exterior contributes to the weight of the unit. You can customize the panel material and thickness with the help of your dealer.

Stainless steel is known for its longevity and efficiency and is a great option thanks to its resilient surface. Aluminum is quite resistant as well and cheaper than stainless steel. However, it is not as durable, and it is susceptible to dents. You will need to increase the thickness of the metal sheets to compensate for aluminum’s shortcomings if you choose to buy an aluminum model. Galvanized steel is the least popular among the three due to its price range. Yet, it is a solid option with high durability and longevity.

18. What Types of Insulation are Used in Walk-ins?

The types of insulation used in walk-ins are as follows:

- Polyurethane Foam: Polyurethane Foam is an excellent insulator and one of the most common choices. Because it is so light, it is easy to install. Polyurethane Foam also has good moisture resistance, which is ideal for refrigerated environments.

- Extruded Polystyrene (XPS) Foam: XPS Foam is another common choice. Because it has high compressive strength, it is very durable. It’s able to withstand the weight of shelves and equipment inside the walk-in. It also has great thermal properties and moisture resistance, which is ideal for refrigerated environments.

- Expanded Polystyrene (EPS) Foam: EPS is a cost-effective and light foam. Although it doesn’t have the same strength as XPS, it is still a great insulation material option and is resistant to moisture.

19. How do Insulation Types Compare in Terms of Benefits?

There are three main types of benefits we can compare in foam insulation:

- Price Points: Polyurethane foam tends to be the most expensive of the three due to its premium quality. Extruded Polystyrene (XPS) foam falls within a moderate price range, slightly pricier than Expanded Polystyrene (EPS) foam yet more affordable than Polyurethane foam. Expanded Polystyrene (EPS) foam is highly cost-effective, striking a favorable balance between affordability and performance.

- R-Value: Polyurethane Foam provides exceptional thermal insulation performance with a high R-value per inch. Similarly, Extruded Polystyrene (XPS) Foam offers high thermal insulation efficiency, though slightly lower than Polyurethane Foam. Expanded Polystyrene (EPS) Foam, while providing moderate thermal resistance compared to Polyurethane and XPS Foam, still offers effective insulation for various applications, albeit with lower R-values.

- Resistances (Moisture and Compressive Strength): Polyurethane Foam offers versatility in different applications because of its high compressive strength and resistance to moisture. Meanwhile, Extruded Polystyrene (XPS) Foam is preferred when structural support and protection against moisture are priorities, owing to its high compressive strength and exceptional resistance to moisture. On the other hand, Expanded Polystyrene (EPS) Foam, with its relatively lower compressive strength and moderate resistance to moisture, finds suitability across various applications.

20. What Types of Cooling Systems are Available for Walk-in Refrigeration?

Cooling systems are made up of five main components: compressor, condenser, evaporator, refrigerant, expansion valve, and the main types of cooling systems are as follows:

- Mechanical-Compression Refrigeration Systems: These systems consist of a compressor, condenser, expansion valve, and evaporator. They are commonly used in commercial applications and operate by compressing and vaporizing refrigerant to absorb heat and cool air.

- Absorption Refrigeration Systems: Instead of a mechanical compressor, these systems use substances that absorb refrigerant, such as ammonia and water. They are quieter, more reliable, and environmentally friendly, making them suitable for industrial refrigeration applications.

21. How Often Do Walk-in Refrigerations Require Maintenance?

Walk-in refrigerations require quarterly maintenance to ensure everything is up to code. Ideally, you should make time for check-ups on a monthly basis and keep an eye on the thermostat, hinges, fans, drains, and similar key points to make sure everything is on track. During your quarterly maintenance, you can get help from professionals, clean the condenser coils, check the fans, pipes, and drains for build-up and blockage, defrost if necessary, and deep clean the whole unit.

22. What are Key Preventative Measures for Maintenance?

Regularly Inspect Door Gaskets: Ensure that door gaskets are clean, intact, and free from damage to maintain proper seals and prevent air leaks, which can compromise cooling efficiency.

- Check Evaporator Coils: Regularly inspect and clean evaporator coils to remove dirt, debris, and ice buildup, which can obstruct airflow and reduce cooling capacity.

- Monitor Temperature and Humidity Levels: You can use temperature monitoring devices to track environmental conditions inside the walk-in cooler and make adjustments as needed to maintain optimal storage conditions for perishable goods. If you spot fluctuations, you should check if the thermostat is calibrated and search for air leaks.

- Defrosting: The defrost cycle is automatically initiated in most walk-ins to avoid frosting and ice build-up. During the defrosting cycle, cooling is temporarily halted to melt the ice and let it go down the drain. Thanks to the insulation and the residual cooling, the perishable items are not particularly in danger during this process.

- Inspect Refrigeration Equipment: You should periodically inspect refrigeration system components, including compressors, condensers, and fans, for signs of wear, corrosion, or malfunction. Addressing any issues in these key areas promptly will prevent equipment failure and ensure uninterrupted cooling.

- Keep Ventilation Ducts Clean: Ventilation is a key component of the cooling process, and you should clean the ducts regularly to avoid dust build-up. By keeping the exhaust fans clean, you can ensure the walk-in runs without issue.

- Schedule Professional Maintenance: Establishing a regular maintenance schedule with a qualified refrigeration technician to perform thorough inspections, cleaning, and servicing of walk-in cooler components can extend the lifespan of your unit significantly. Professional maintenance helps identify and address potential problems before they escalate, ensuring reliable performance and extending the lifespan of the equipment.

23. What Safety Features Should be Included in Walk-ins?

The following safety features should be included in the design of the walk-in unit to prevent accidents and health hazards:

- Two-Sided Access: Access doors of walk-in refrigerated spaces must be operable from both inside and outside.

- Safety Releases from Inside: If doors have latches or locks, there must be a mechanism for users inside to safely release them without tools or keys or an alternative clearly marked exit.

- Alarm: There must be a means of raising the alarm from inside the space, such as a phone or monitored alarm system, in case of entrapment.

- Emergency Exit Signs: Independent emergency lighting must indicate the exit and safety devices.

- Occupancy Indicator Lighting: Lighting within the space should activate an indicator lamp outside to show occupancy, and all emergency lighting and switchgear must be appropriately labeled.

24. What Type of Glass Doors are Recommended for Walk-ins?

The type of glass doors recommended for walk-in refrigeration depends on factors such as energy efficiency, visibility, and durability:

- Heated Glass Doors: Heated glass doors are designed to prevent fogging. If you live in a humid area and do not have air conditioning during the summer months, you will need heated glass to keep the interior of the walk-in visible.

- Low-E Glass Doors: Low-emissivity (Low-E) glass doors have a thin coating that reflects heat while allowing visible light to pass through. This helps regulate indoor temperatures and reduce heating and cooling loads on the refrigeration system, resulting in energy savings.

- Insulated Glass Doors: Insulated glass doors consist of multiple layers of glass separated by insulating spacers. They help maintain consistent temperatures inside the walk-in, reducing energy consumption and improving food safety.

- Safety Glass Doors: Safety glass doors, such as tempered or laminated glass, are recommended for walk-ins to enhance durability and prevent injury in case of breakage. Tempered glass is heat-treated to increase strength and shatter resistance, while laminated glass consists of multiple layers bonded together to prevent splintering.

25. How Do I Choose the Right Refrigeration System for My Walk-in and Determine the Necessary Size?

You can choose the right refrigeration system and determine the necessary size for your walk-in by understanding what each entails and considering your special circumstances. The necessary size hinges on the storage demands of your business. You should assess your needs, track your purchases, and figure out how much space you need.

- Remote Systems: These systems consist of a condensing unit, an evaporator unit, and additional components like expansion valves and thermostats. Remote systems offer the advantage of locating the condensing unit outside the building to minimize heat addition to the interior. Thanks to this feature, you will gain more space indoors and can invest in a bigger unit.

- Standard Top Mount: Self-contained refrigeration systems with all parts, copper lines, and refrigeration gases pre-installed. These systems may occupy shelf space and headroom inside the walk-in. You should take this loss of space into consideration when calculating your capacity needs.

- Side Mount Refrigeration System: These models are installed on a wall panel, requiring bolts through the refrigeration plug and wall panel. They may also sacrifice shelf space inside the walk-in.

- Penthouse Refrigeration System: These systems are quite space-saving in design. They are similar to top mount systems but without an evaporator coil inside the walk-in. While seeming higher in upfront cost, they are less expensive in the long run due to factory assembly and space-saving design.

- Pre-assembled Remote Systems: Similar to remote systems, all components come pre-installed on either the condensing unit or the evaporator coil. They are pre-charged with refrigerants and can be situated outdoors to prevent extra heating of the unit.

26. What Customization Options are Available for Walk-ins to Meet Specific Business Needs?

You can customize your walk-in cooler or freezer in the following ways to meet specific business needs:

- Size and Layout: Custom dimensions to fit available space, including compact designs for tight spaces or expansive layouts for high-volume storage. Modular components allow for easy expansion or reconfiguration.

- Temperature Zones: Multi-temperature units with separate sections at different temperatures for businesses that require varied storage conditions, such as restaurants or supermarkets with both refrigerated and frozen products.

- Shelving and Storage Solutions: Adjustable and heavy-duty shelving options to accommodate specific item sizes and weights, from liquor bottles in bars to large food trays in cafeterias.

- Door Types and Locations: Customizable door sizes, types (sliding or swing), and placements to enhance workflow efficiency and accessibility are important for high-traffic environments like convenience stores and hospitals.

- Flooring Options: Choice of flooring materials, including reinforced options for heavy equipment or non-slip surfaces for safety in wet areas, suitable for medical labs or butcher shops.

- Insulation and Panel Materials: Enhanced insulation options for energy efficiency and durability in various climates are critical for businesses in extreme weather locations, like resorts or governmental installations.

- Exterior and Interior Finishes: Custom finishes to match business aesthetics or for compliance with health and safety standards, essential for hospitality groups and senior living centers.

- Refrigeration Systems: Selection of refrigeration systems based on capacity, efficiency, and noise levels, catering to the specific operational demands of schools, clubs, or religious centers.

- Security Features: Advanced security features like lockable doors and access control systems for sensitive storage in hospitals, military installations, and funeral houses.

- Health and Safety Compliances: Compliance with health and safety regulations, including NSF certification and ADA-compliant designs, is vital for institutions, schools, and medical facilities.

- Monitoring and Alarms: Integrated monitoring systems and alarms for temperature regulation and emergency alerts, providing peace of mind for businesses like medical labs and gas stations where product integrity is crucial.

- Lighting Options: LED lighting for energy efficiency and better visibility, enhancing product display in supermarkets and convenience stores.

- Outdoor vs. Indoor Installation: Options exist for both indoor and outdoor installations, with weatherproofing for outdoor units. This allows flexibility for businesses with limited indoor space, such as gas stations and small clubs.

27. How Easy is the Installation Process for a Walk-in?

The installation process for a walk-in cooler or freezer is fairly easy, thanks to the detailed labeling and instructions provided by manufacturers. Plus, most new models include a cam lock system in panel connection, which means the process of connecting panels is now easier and more reliable. However, you will need the help of professionals to carry out the entire installation without a problem. Even though the assembly isn’t super difficult, there are many different areas that need to be taken care of, ranging from air conditioning to plumbing and wiring.

28. Is It Possible to Assemble a Walk-in on Your Own?

No, it is not possible to assemble a walk-in on your own. You will need an HVAC technician and several other professionals to do so. Aligning the panels, integrating the unit into the existing infrastructure, and installing the refrigeration mechanism requires a professional touch, and trying to do these on your own can lead to accidents or threaten the integrity of the walk-in.

29. What Should be Considered When Ordering and Shipping Walk-in Refrigeration to Ensure Safety and Track the Process?

When ordering and shipping walk-in refrigeration to ensure safety and track the process, several factors should be considered:

- Customization Options: If you ordered a custom model, verify before production and shipment that the customization requests are well-communicated and received. Customizations can include modifications such as custom panel sizes, door placements, shelving arrangements, and additional features such as windows or specialized shelving units. Consider your needs and communicate your customization requests clearly when ordering.

- Expandability: Consider the potential for future expansion or modifications to the walk-in refrigeration when placing your order. Choose systems that allow for easy integration of additional panels, doors, or accessories as business needs evolve. This ensures scalability and flexibility to adapt to changing storage requirements over time.

- Ease of Assembly: Walk-in units are large pieces of equipment, and you will definitely need an HVAC engineer to help assemble the whole thing. However, you can still select models that are designed for ease of assembly and installation. Look for systems with user-friendly assembly instructions, pre-engineered components, and modular construction that simplify the installation process. This helps minimize installation time, labor costs, and potential errors during assembly.

- Shipping Company and Insurance: Make sure to work with a reputable shipping company to handle the shipping to avoid accidents and damages. Through the shipping company’s website, you can track the movements of your unit and set a delivery date easily. You can get the unit insured in case of mishaps and minimize your losses.

30. Which Certifications are Important for Walk-ins?

Certifications such as NSF, UL, and CE Marking are important for walk-ins to have to pass inspections. They verify the quality, efficiency, and safety of the product and ensure you are up to code.

- NSF: NSF (National Sanitation Foundation) standards ensure that walk-in refrigerations meet specific requirements for food safety, sanitation, and structural integrity. NSF International provides certification for various components and materials used in walk-in refrigeration units.

- UL Certification: UL (Underwriters Laboratories) certification ensures that walk-in refrigerations comply with safety standards and requirements established by UL for electrical components and systems. UL certification signifies that the unit has undergone rigorous testing and evaluation for safety and performance.

- CE Marking (Europe): CE marking is a European certification that is absolutely needed if you operate in the EEA. The certificate indicates compliance with the European Union (EU) safety, health, and environmental protection regulations.

31. How can I Ensure That the Walk-in Refrigeration I Choose will Be Scalable and Adaptable to My Business’s Changing Needs, Such as Menu Expansions or Increased Customer Capacity?

To ensure your walk-in refrigeration system is scalable, opt for modular designs that allow for easy expansion. Look for units that can be customized with additional shelving or cooling capacity to accommodate increased demand. Also, consider systems with adjustable controls and smart technologies that adapt to varying storage requirements, providing flexibility as your business evolves. It’s wise to consult with a dealer and manufacturer about the potential for future enhancements to your selected walk-in model to ensure long-term adaptability.

32- What Factors Should I Consider When Selecting a Walk-in Cooler and Freezer Combo to Optimize Both Space and Efficiency in My Establishment?

When selecting a walk-in cooler and freezer combo, consider the size and layout to ensure it fits your space while offering sufficient storage. Energy efficiency, temperature control, and compliance with health standards are crucial. Choose a model with a reliable insulation system and adjustable shelving for maximum space utilization and operational efficiency. It’s also important to evaluate the unit’s adaptability to your specific workflow and the availability of service and parts for maintenance.

33. Where can I find Additional Information for Further Information on Walk-in Refrigeration?

For additional information on walk-in refrigeration, read our walk-in guide, visit our website, and contact us via a form or call. If you are near Nashville and Murfreesboro, visit our stores.