Bag Sealers

Instant Packaging With Bag Sealers

Bag sealers, also known as heat sealers or impulse sealers, are a fast and efficient way of packaging your food items. This heat-based sealing method provides a rapid and fully automatic wrapping process in seconds. They can seal any products, from sweets and cookies to meats and veggies, as long as they are placed in food-safe plastic bags. Their primary advantage over other food packaging machines is the operation speed and ease, requiring less energy, skill, and labor.

How Bag Sealers Work

Depending on the model, bag sealers feature a sealing bar at various lengths, ranging roughly from 8 to 25 inches. The bar size specifies the bag widths you can use with your sealer. If you run a confectionery, you will often use small bags to wrap your sugar candies, chocolates, cakes, and cookies. A heat sealer with a bar size of 12-15 inches would be more than enough for you.

Bag sealers use an impulse of electricity to heat the sealer bar. The current flows through the sealer wire to create instant heat. You put your items in a food-safe plastic bag and place it in the device. The machine uses heat just enough to melt the plastic so that it sticks firmly. This creates a nice airtight seal for products to stay fresh longer on the counter, in the pantry, or refrigerator. These handy gadgets enable you to make customized gifts or confectionery bags.

Different Bag Sealer Types

Bag sealers are widely used in various industries due to their efficiency. Therefore, several types have evolved to cater to each industry’s unique needs. A handheld heat sealer looks very much like a big stapler. Although it occupies almost no space with a compact design, it achieves a strong watertight seal. Countertop models are also compact but require some room on a counter or tabletop. They are perfect for coffee shops, confectionery stores, restaurants, produce stands, supermarkets, and convenience stores.

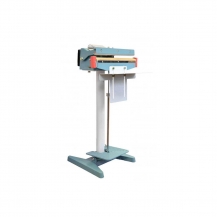

The freestanding bag sealers are designed for high-volume applications. They have sturdy construction to withstand heavy-duty use in commercial and industrial environments. They offer hands-free and safer operation with a foot pedal. With adjustable heat and time controls, these impulse sealers can seal plastic bags of various thicknesses in less than 3 seconds. If you often use thicker bags for your large products, you can depend on the freestanding heat sealers.

Bag Sealers Or Vacuum Sealers?

Both vacuum and bag sealers utilize electricity to heat the sealing bar. However, bag sealers provide impulse heat for only a few seconds. Vacuum sealers are constant-heat sealers that supply higher levels of heat. They seal bags at higher melting points, so they work better with thicker materials, which makes them more versatile food packaging machines. Impulse sealers heat up and cool down instantly on demand. They require no pre-heating. Therefore, they can save you time and money.

Bag sealers offer a more economical way of packaging products for protection, storage, or display. Chef’s Deal has impulse sealers from trusted brands, Alfa International, Eurodib USA, Omcan USA, and more.